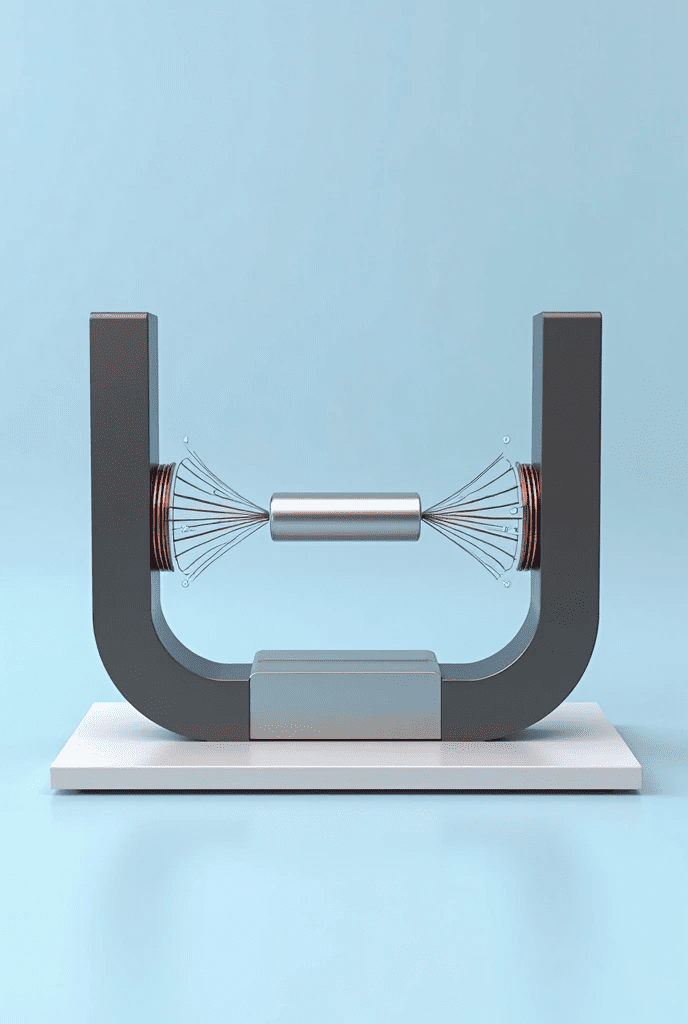

A New Paradigm of Magnetic Control Architecture

The NIMEC motion-less system is built on a fundamentally different interpretation

of magnetic interaction, where motion, torque, and mechanical transfer are no

longer mandatory elements of energy conversion. At the core of the system lies a

fully closed magnetic circuit assembled from two identical laminated U-shaped

electrical steel cores, positioned symmetrically and facing each other to form a

rigid rectangular magnetic frame. Permanent neodymium magnets are mechanically

pressed directly between the core legs and integrated into the magnetic path

without intentional air gaps, ensuring maximum flux continuity and minimal

magnetic resistance.

Unlike conventional electromagnetic systems that rely on externally generated

fields and continuous electrical excitation, this architecture uses the intrinsic

field energy of permanent magnets as the primary working medium. The magnetic

flux is entirely confined within the structure, circulating through

high-permeability steel and magnets in a predetermined path. There is no open

magnetic field, no stray dissipation, and no dependency on rotating shafts,

bearings, or classical electromechanical assemblies. Motion, in its traditional

mechanical sense, is replaced by controlled internal reconfiguration of magnetic

states.

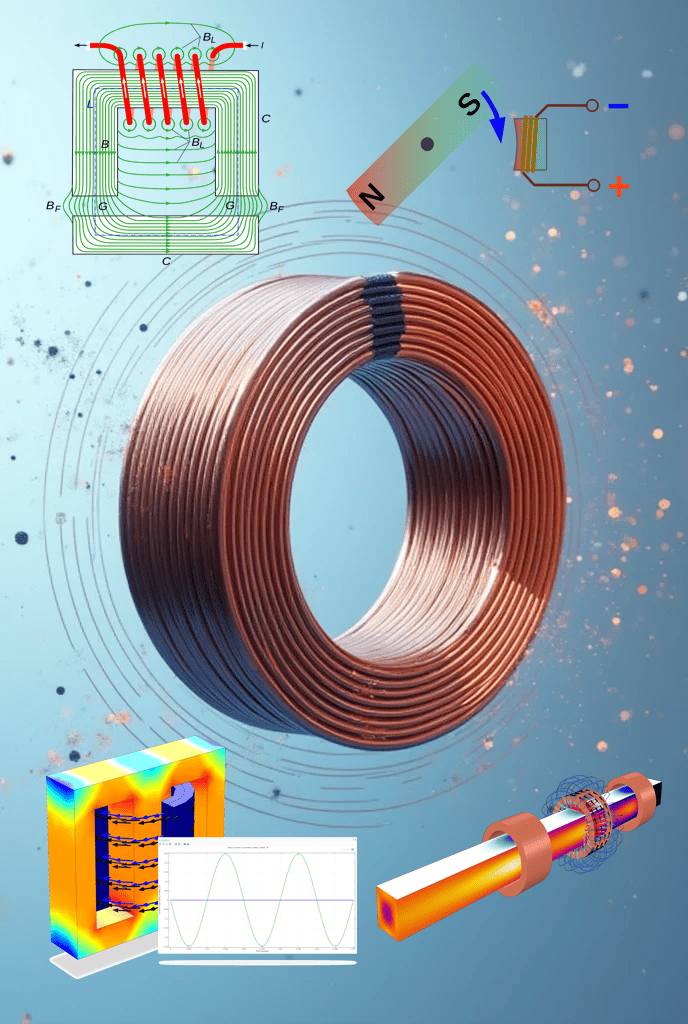

This approach eliminates many structural and energetic limitations inherent to

classical machines. Mechanical losses, friction, vibration, and wear are

inherently excluded by design. The system operates as a solid-state magnetic

framework in which geometry, material selection, and magnetic polarity define a

stable baseline energy condition, forming the foundation for controlled

field-based operation rather than mechanically enforced movement.