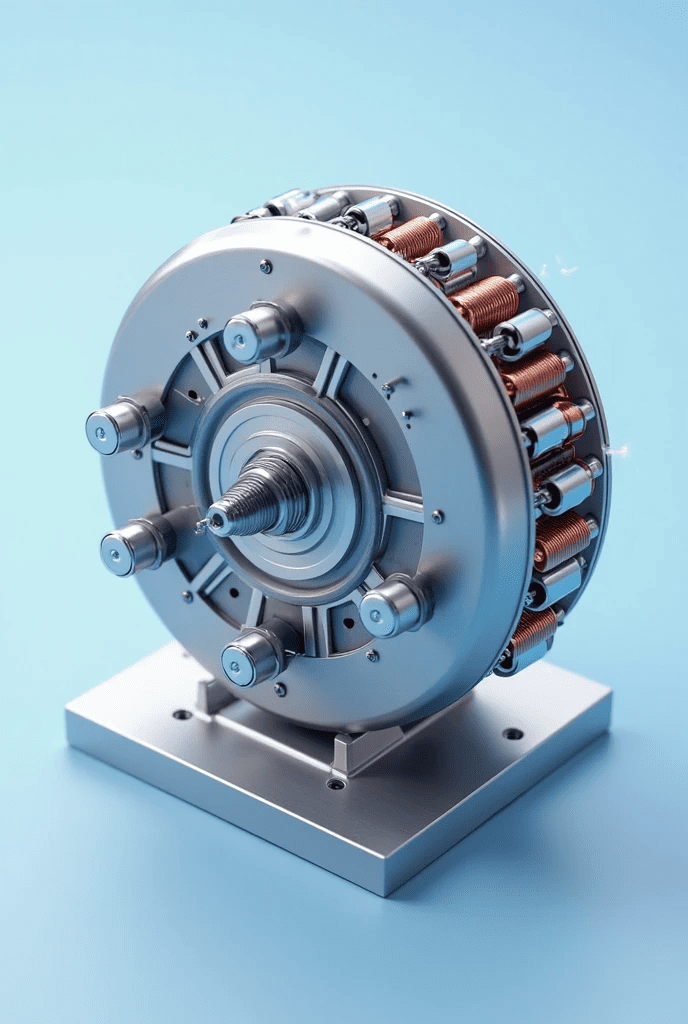

Tailored Solutions for Industrial Motion and Efficiency

At NIMEC, every motor is custom-built — we do not produce standard, off-the-shelf

solutions, but design and manufacture units tailored precisely to the specific

requirements and tasks of each client. This approach allows the system to be

adapted to the characteristics of the mechanism, operational conditions, and

desired power output, creating unique solutions unavailable from mass-market

manufacturers. Our motors can drive shafts of various industrial mechanisms,

hydraulic pumps, and fluid systems of any type — from water to specialised

technical fluids — providing stable rotation and maximum efficiency.

The cost of each unit is determined by a variety of factors: power, geometry,

materials, durability requirements, and specific operational conditions.

Pricing is calculated individually to ensure an optimal balance between

efficiency, reliability, and economic feasibility. This approach allows

our clients to accurately plan their investments, achieve high returns

from technology implementation, and have confidence that the motor perfectly

meets their production and technical needs.

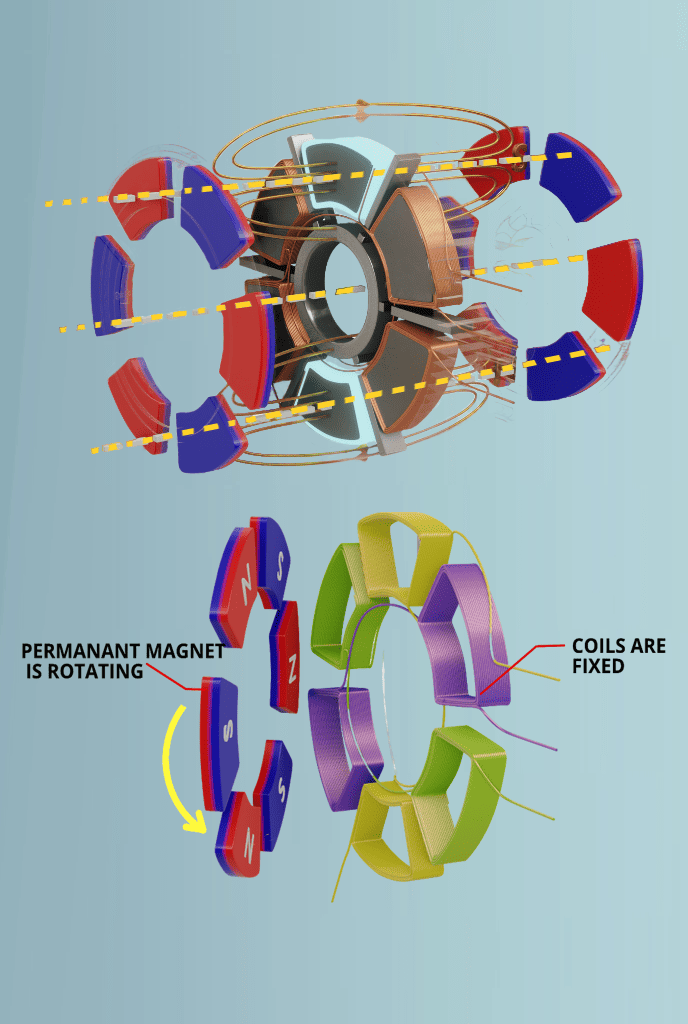

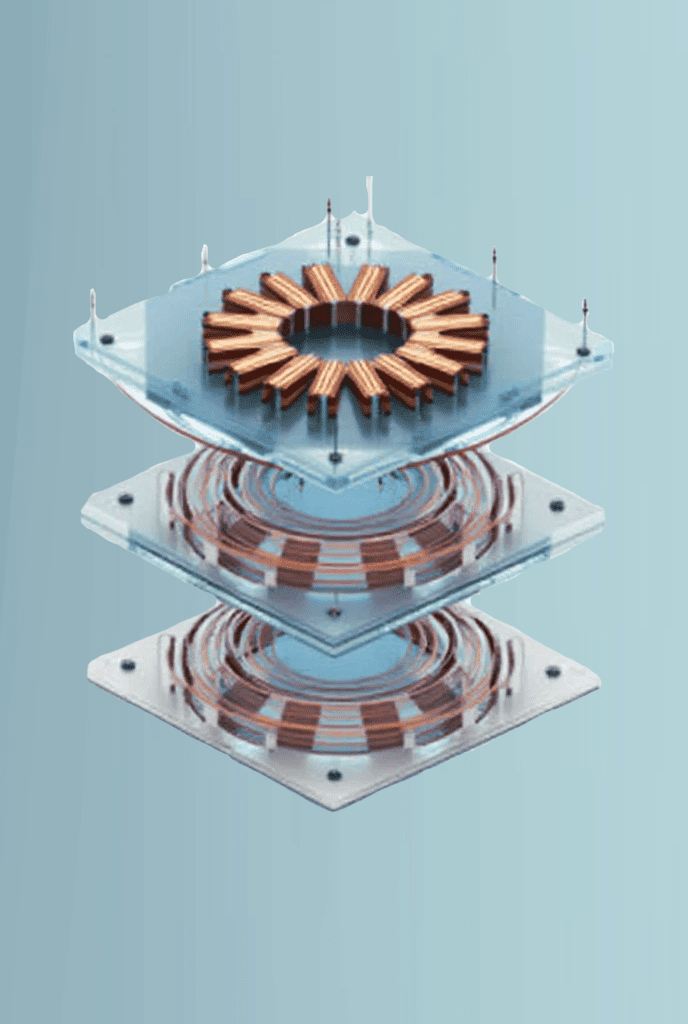

Every NIMEC solution is not merely a motor, but a tool for enhancing productivity

and economic performance, where engineering precision and innovative magnetic

technologies combine to transform the potential of magnetic fields into tangible

advantages for your business.