N NIMEC has developed a unique solution that enables the rotation of a vessel’s propeller without the use of a conventional internal combustion engine, and therefore without the consumption of traditional marine fuel.

W We utilize only standard equipment certified for marine applications by leading global manufacturers, such as: Bosch Rexroth — a world leader in marine hydraulics and drive systems; Danfoss Power Solutions — a developer of reliable hydraulic motors for heavy-duty environments; Parker Hannifin — a supplier of hydraulic solutions for shipbuilding and maritime industries; Linde Hydraulics — a manufacturer of high-efficiency hydraulic motors and pumps for marine vessels and etc.

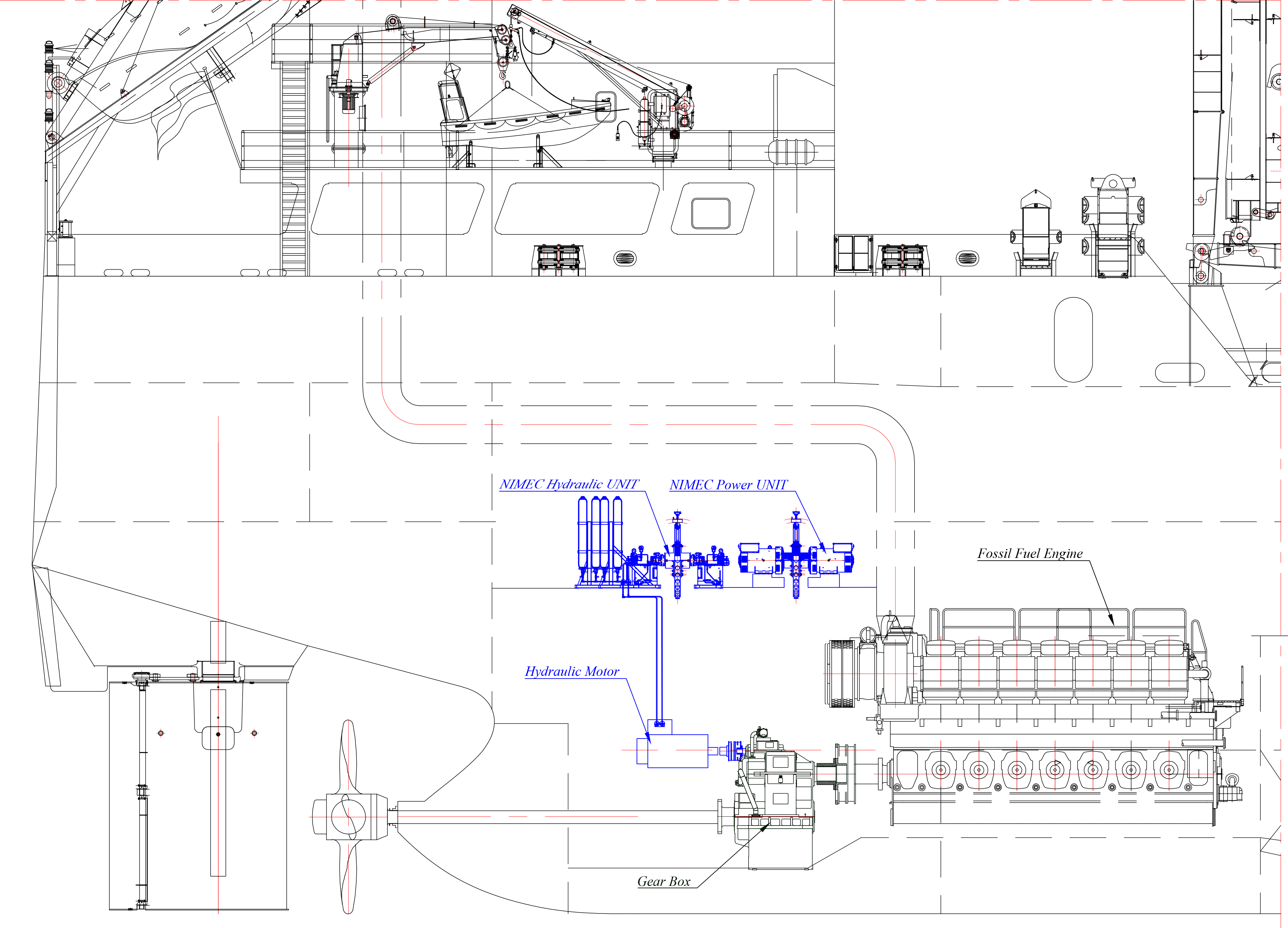

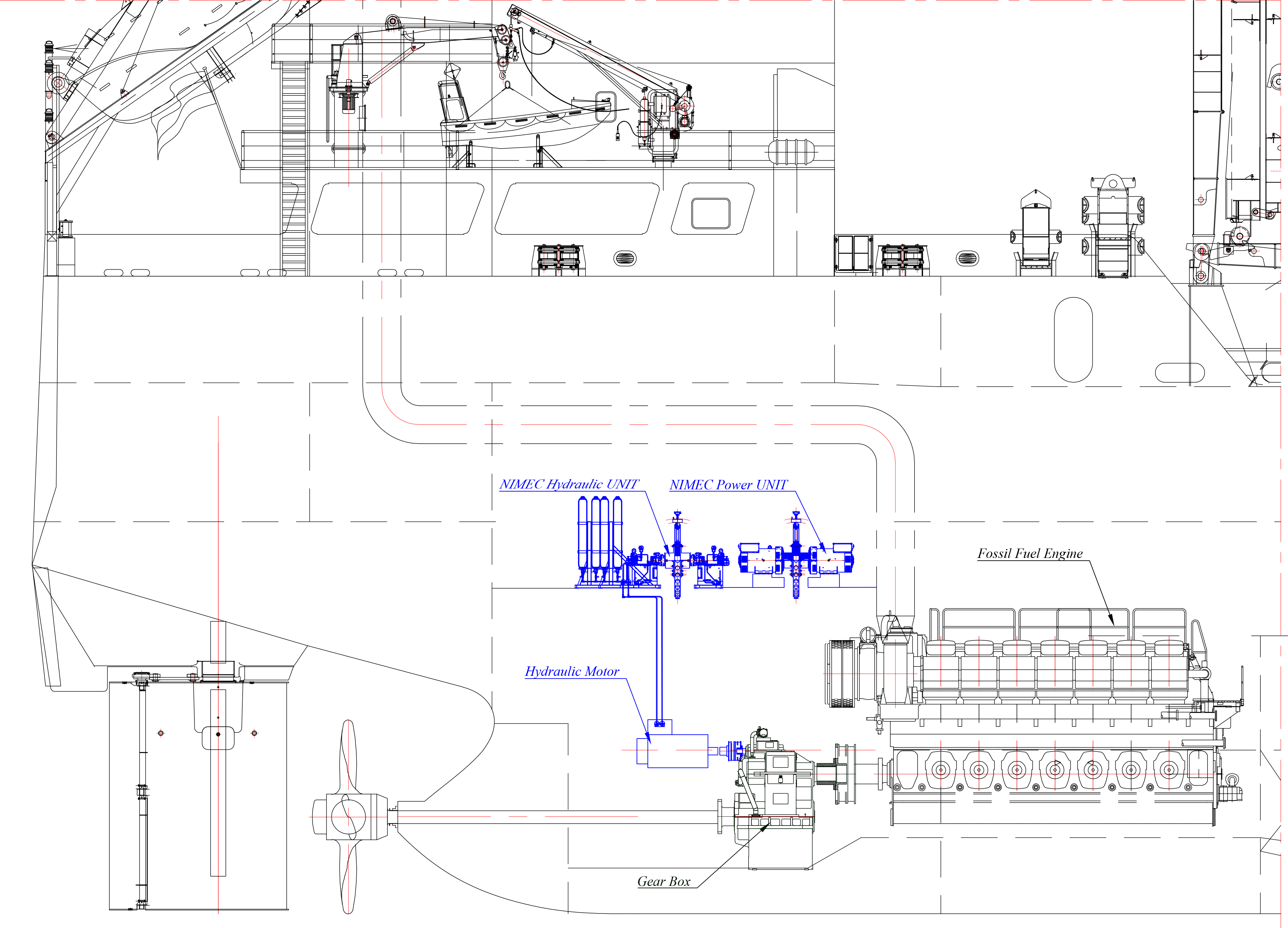

O Our solution does not require any redesign or removal of the vessel’s existing propulsion system. All equipment is installed additionally, integrating seamlessly with the ship's current mechanisms. This approach enhances the vessel’s reliability and allows for the use of two independent propulsion systems — selectable by the crew depending on the maritime conditions.

T The use of traditional marine fuels — among the most polluting fuel types — leads to significant environmental and economic consequences. Under the International Convention MARPOL Annex VI, emissions of sulphur oxides (SOx) and nitrogen oxides (NOx) from ships are strictly regulated. Since 2020, the maximum allowable sulphur content in marine fuel has been reduced to 0.5% globally and to 0.1% within Emission Control Areas (ECA), such as the North Sea, Baltic Sea, North American coasts (USA and Canada), and major European ports (e.g., Amsterdam, Hamburg, Oslo).

I In many "green" ports, vessels operating on heavy fuel oil without exhaust gas cleaning systems (scrubbers) are either prohibited from entry or subject to fines of up to €25,000 for violations (for instance, in ports across Germany and the Netherlands). Additionally, the cost of heavy marine fuels continues to rise — on average, they are 20–30% more expensive than alternative solutions, while the operational expenses associated with scrubbers further increase shipping costs.

W We connect a hydraulic motor of appropriate capacity to the shaft or the existing gearbox of the vessel’s engine. In most cases, for small to medium-sized vessels, where the power of a single propeller does not exceed 800 kW, this fully matches the specifications of standard, certified hydraulic motors proven through extensive operational use. Propeller rotation speeds typically range from 200 to 300 rpm, which is ideal for hydraulic motors.

T The hydraulic motor is connected to a hydraulic power unit (HPU) via high-pressure oil supply and low-pressure return lines. The configuration of the HPU is selected individually based on the specifications of the chosen motor, using only standard, industrial-grade, marine-certified solutions. The HPU is powered by electricity generated by our proprietary autonomous energy system. This system is based on the conversion of energy through the interaction of permanent magnet and electromagnetic fields, ensuring stable, reliable, and environmentally friendly energy supply — with zero emissions and no fuel costs.

F For vessels with larger installed propulsion power, it is necessary to undertake a detailed project analysis and develop a tailored solution. In such cases, we design combined systems employing multiple hydraulic motors, load distribution strategies, and optimized equipment layouts to match the vessel’s specific requirements. This approach ensures reliability, efficiency, and full compliance with classification society standards.