N NIMEC has developed an advanced autonomous power generation system, based on the dynamic interaction of magnetic fields produced by permanent magnets and controlled electromagnets. This pioneering technology enables the central generator to be driven without the use of fuel, mechanical linkages, or external energy sources — delivering true energy independence for commercial vehicles and heavy-duty transport.

A At the heart of this innovation lies a seamless blend of physics and intelligent engineering: permanent magnets provide a stable and enduring magnetic field, while precisely controlled electromagnets dynamically interact with it to generate continuous rotational force. This torque directly drives a high-efficiency generator, producing a stable flow of electricity to power all onboard systems — from traction motors to auxiliary equipment. Unlike conventional solutions, the NIMEC system operates entirely without emissions, fuel consumption, or the wear and maintenance costs associated with internal combustion engines.

Operating principle

P Permanent magnets establish a stable and uniform magnetic field, providing a consistent baseline of magnetic flux essential for continuous system operation. This static magnetic field serves as the foundation for the interaction with dynamic magnetic fields generated by the electromagnets. Owing to the inherent properties of high-grade permanent magnet materials, such as neodymium-iron-boron (NdFeB) or samarium-cobalt (SmCo), the magnetic field remains unaffected by typical environmental variations, including temperature fluctuations, vibrations, or mechanical stress.

W We have succeeded in optimizing the principle of Nikola Tesla’s battery switch. This optimization involves the use of supercapacitor modules and modern electronic components to achieve efficient switching. By passing electric current through electromagnets with differently oriented windings, we create magnetic fields of varying polarity. These dynamic magnetic fields interact with the stable field of the permanent magnets, whose polarity remains unchanged, resulting in the rotation of the rotor equipped with permanent magnets and consequently generating mechanical torque on the shaft.

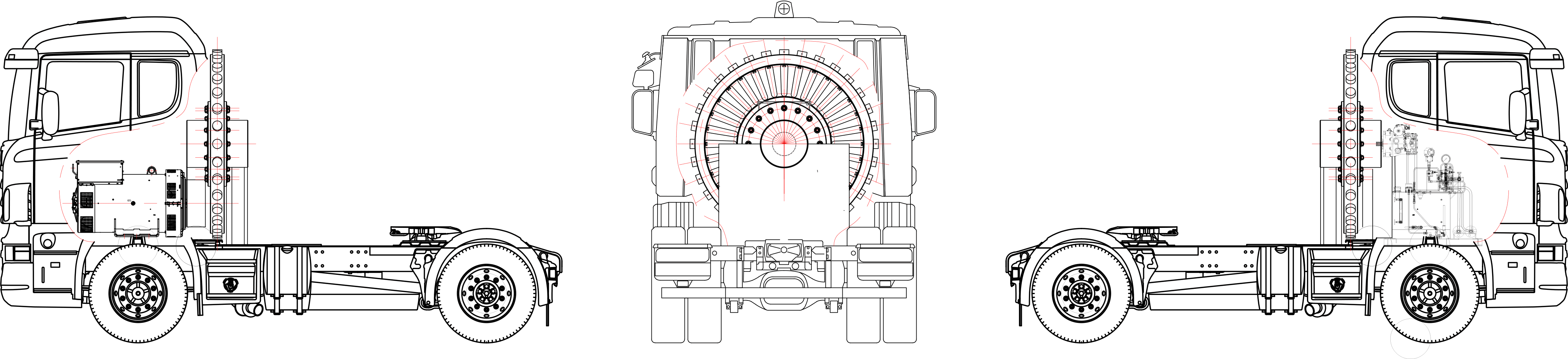

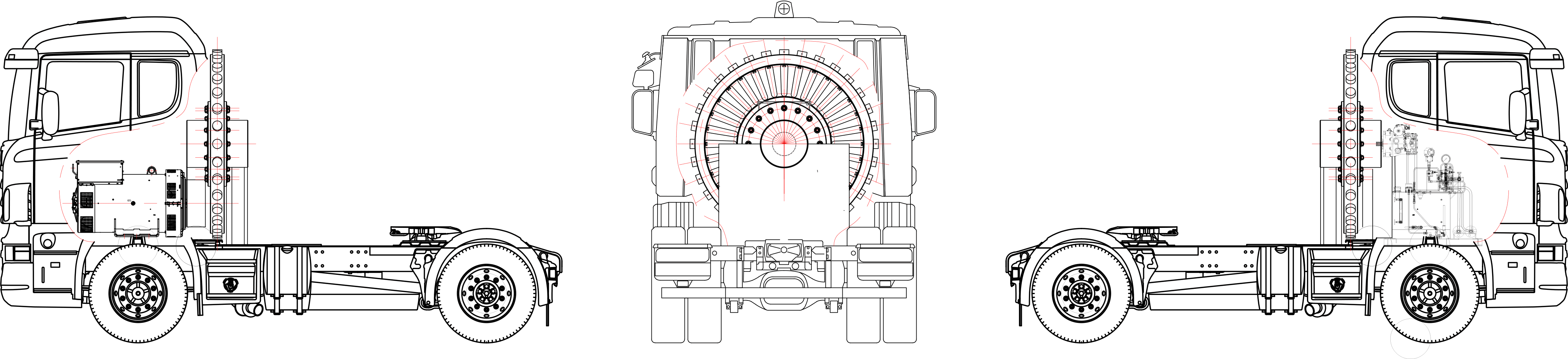

T The rotor shaft of the magnetic drive motor is mechanically coupled to the shaft of the main generator. The generator is carefully selected based on the required electrical output to fully supply all onboard systems of the truck, including traction motors, auxiliary systems, and battery charging modules. The mechanical torque produced by the magnetic motor is transmitted without intermediate gear reductions, ensuring minimal mechanical losses and maximum efficiency. As the coupled shafts rotate, the generator converts the rotational mechanical energy into electrical energy, providing a continuous and stable power supply tailored to the operational demands of the vehicle.

Key Features

C Continuous operation is ensured without the need for downtime or external battery recharging. The autonomous power generation system delivers a constant real-time energy supply, allowing traction motors, auxiliary systems, and batteries to function seamlessly. This guarantees uninterrupted performance and maximizes vehicle availability across all operating conditions.

T The system operates entirely without combustion processes, eliminating the release of carbon dioxide (CO₂), nitrogen oxides (NOₓ), sulphur oxides (SOₓ), particulate matter, and other pollutants commonly associated with internal combustion engines. As a result, the vehicle achieves a fully sustainable and environmentally friendly performance, meeting and exceeding the strictest global emission standards without the need for additional filtration or after-treatment systems.