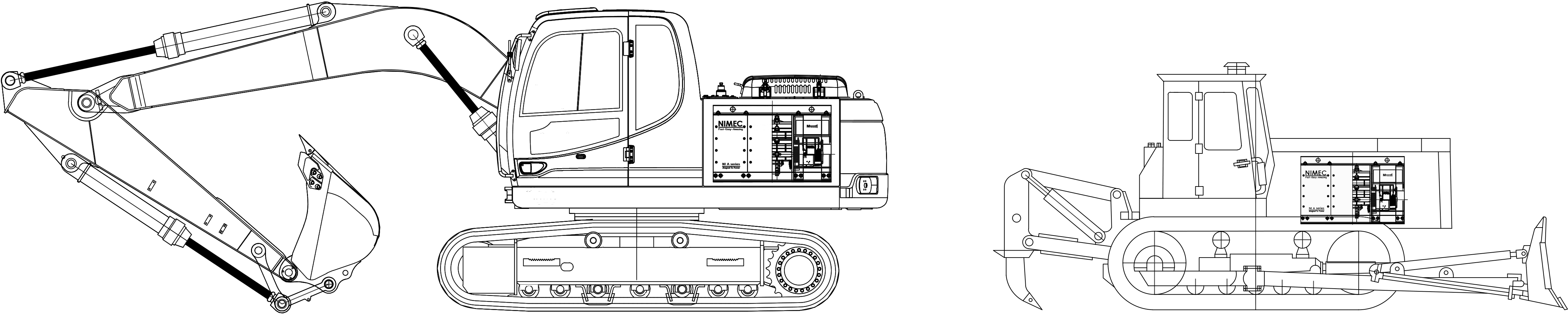

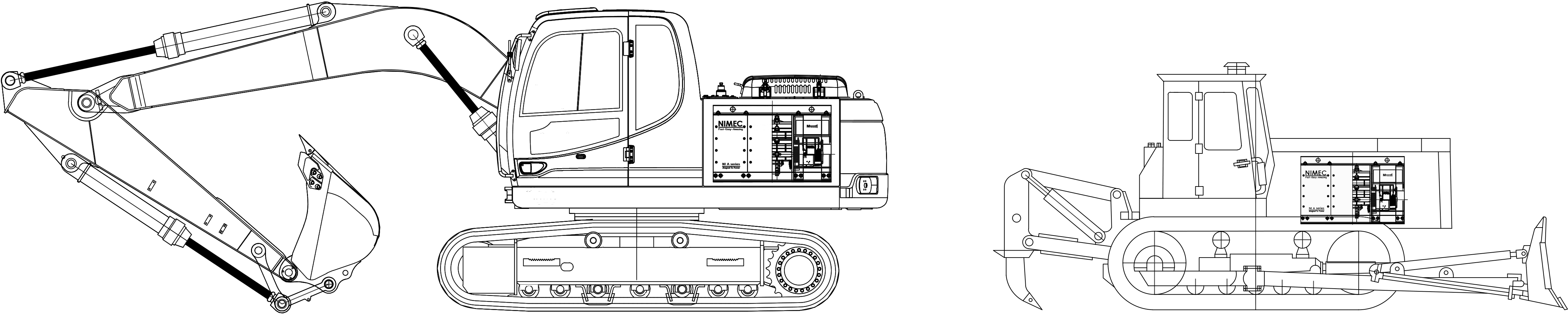

M Modern heavy-duty tracked construction and mining equipment predominantly relies on hydraulic motors. These systems deliver exceptionally high torque, precise control, and outstanding durability, making them ideal for extreme operational conditions. Hydraulic drive technology ensures maximum efficiency, reduced mechanical complexity, and superior performance under heavy loads, establishing it as the gold standard for today's most demanding industrial applications.

B By integrating our magnetic motor with a hydraulic pump directly coupled to its rotor shaft, it becomes possible to generate a continuous flow of hydraulic fluid at precisely controlled pressures. This hydraulic output can be used to drive one or multiple hydraulic motors, delivering powerful, efficient, and reliable mechanical motion.

O Our innovative solution revolutionises traditional hydraulic systems by offering a clean, fuel-free source of hydraulic power. Designed to seamlessly replace or enhance conventional setups, it delivers consistent, high-performance energy perfectly tailored for the heavy-duty demands of construction, mining, and industrial equipment. With zero fuel dependency and reduced maintenance needs, our system not only boosts operational efficiency but also sets a new standard for sustainable power in the most challenging environments.

Highlighting the Key Benefits

1st Elimination of Internal Combustion Engines. Our system completely removes the need for traditional internal combustion engines, resulting in zero exhaust emissions, significantly reduced noise levels, the absence of heat signatures, and no requirement for on-site fuel delivery.

2nd Simplified Mechanical Architecture. By eliminating the need for traditional transmissions, complex control systems, and heavy-duty braking mechanisms, our solution reduces mechanical complexity, enhances reliability, and lowers maintenance requirements.

3rd Rapid Energy Module Replacement. Even if the supercapacitor modules become depleted, they can be swiftly replaced on-site, allowing heavy tracked machinery to resume operations with minimal downtime.

4th Enhanced Mobility and Redundancy. Unlike traditional systems that rely on a single drive sprocket per track, our solution enables the use of multiple powered wheels along the track. This design ensures that even in the event of track damage or partial failure, the vehicle retains mobility and operational capability.

5th Compact, Lightweight, and Easily Serviceable Design. Our system is significantly more compact and lighter than traditional drive systems, simplifying installation and improving overall efficiency. Thanks to its modular construction, damaged components can be quickly replaced on-site, ensuring minimal downtime and reduced maintenance costs.

6th Explosion-Proof, Fire-Safe, and Environmentally Neutral. Our system eliminates the risk of explosions and fires associated with traditional fuel-based machinery. With no combustion process and no hazardous emissions, it offers an exceptionally safe operation and maintains a minimal environmental footprint, making it ideal for sensitive and demanding environments.