Give your dreams a shape of reality

C Currently, the world continues to face two main problems - energy and raw materials. The energy problem is the lack of energy to meet the needs of the population and develop the economy. The resource problem is associated with limited supplies of natural resources such as oil, gas, coal and metals. The problem of resource shortages is directly related to energy shortages. Accordingly, solving the problem of energy shortages is a priority.

NIMEC present a unit for generating electricity without harming the environment using gravity force of heavy fluid fall. Our unit generate the electricity using the circulation of working heavy fluid in a closed cycle. Therefore, the unit can be classified as a HYDROPOWER one. The electricity obtained as a result of our unit running is completely meets the definition of GREEN ENERGY.

W We do not present any inventions or untested devices. We use our know-how of the correct, from our point of view, order of connecting devices and their operating modes. The unit we present has a main feature - no any fossil fuel requiremnt for generating electricity.

When we say that our station is Fossil Fuel Less, we mean that it does not need traditional types of fuel and, accordingly, there are no costs for its acquisition, creation of infrastructure for its delivery, storage and preparation for use. Of course, the station uses fuel - this is energy of magnetic field and the energy of Earth's gravity.

E Environmental pollution with exhaust gases from generating stations, waste from chemical (combustion) and nuclear reactions is the main problem of large-scale electricity generation. Changes in the ecological system of rivers, fields and places where there is enough wind occur with the use of hydro, solar and wind power plants.

In general, all existing electricity generation affects the climate, ecology and environment. This sad conclusion prompted us to present a new electricity generation system using existing mass-produced devices and mechanisms.

M The station can and should be divided into blocks - Modular structure, the placement of each module canbe on faew distance from each other. The location of each module does not depend on the presence of the sun, wind, rivers and other factors necessary for traditional power plants.

The reliability and durability of hole station is determined by the closed cycle of operation, the quality of the equipment used and its periodic maintenance. Efficiency in operation and maintenance determines the reliability of the system and its independence from external factors (wars and embargoes and, as a consequence, the impossibility of supplying raw materials, not possible to hack and so on).

Description of the unit operation

Traditionally, energy is generated by rotating a magnetic field around a coil of wire and thereby exciting an emf force in the coil. In this way we transform mechanical energy into electrical energy.

We will not break tradition and will use a rotating shaft with generators, a turbine and flywheels connected to it. To reduce energy losses on the shaft, we will use generators with the same required rotation speed and select a suitable turbine for them. In this way we avoid the use of reducers and energy losses due to their use.

To ensure proper and uniform distribution of rotational energy, we will use generators on both sides of the turbine (see figure below).

To ensure smooth rotation and smooth out jerks that can be caused by both generators and turbines, we will use flywheels.

Generators are divided into two groups. The first group only supplies energy to the power-consuming network. The second group supplies electricity to all the mechanisms and devices of the station. Permanent magnet generators are used during operation. Synchronous generators with permanent magnets (PMG) have a number of advantages in that they have a simple electrical circuit, do not consume energy for excitation and have increased efficiency, are highly reliable, and are less sensitive to the armature reaction than conventional machines.

The rotation of the shaft and the entire system is ensured by a bucket turbine. We choose a bucket turbine because it does not require high fluid flow. Flow - this factor is very important, since its provision will ensure the entire operation of the system.

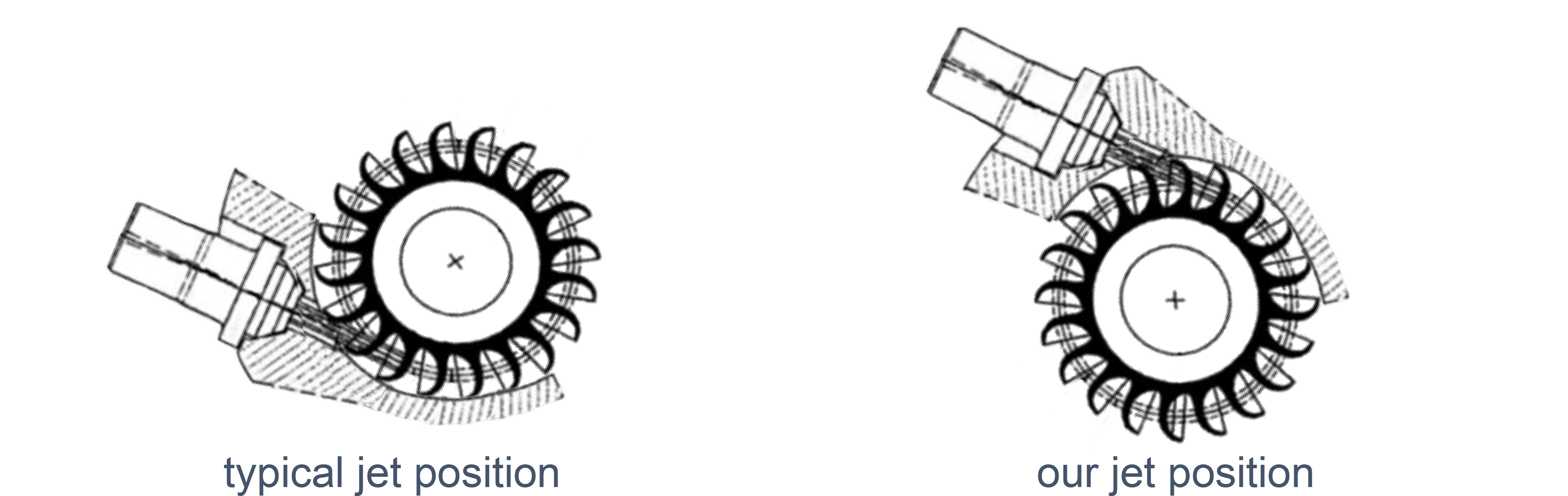

To minimize fluid consumption and more efficient rotation of the turbine, we use heavy fluid and vertical supply to the turbine. Due to the low flow rate and relative low weight of water, a lower fluid supply to the turbine is usually used for ease of drainage. We, using heavy liquid, instead pass the stream through as many buckets as possible. Also, by increasing the diameter of the turbine, we achieve a reduction in the force required to rotate the generators under load. We can achieve this by using PMG with a required rotation speed of about 600 rpm.

We use an 80% solution of Zinc Iodide ZnI2·H2O CAS 10139-47-6 as a heavy liquid. This gives us an increase in the weight of the circulating fluid almost four times compared to water. This substance is ideal as it is the least harmful to the environment and the cheapest to use. It should also be noted that the heavy liquid circulates in a hermetically sealed closed cycle and its quantity is the minimum possible.

The heavy liquid receives the energy necessary for circulation and rotation of the turbine in a piston cylinder, the piston of which transfers the energy of compressed air to the heavy liquid and pushes it out with the necessary pressure. These piston cylinders do not have a rod and are located vertically to use the forces of gravity when deflating air and filling the cylinder. The compressed air flow and the heavy liquid flow are equal to reduce losses, the dimensions and number of cylinders are calculated from this correspondence.

Compressed air is produced by our Magnet to Power Units. The Units compresses the air to a pressure of 350 bar. The Units are powered by Magnetic Field Attraction Force resulting from action of permanent and electrical magnets and electricity produced by the second group of generators.

Thus, we convert the kinetic energy of compressed air into potential energy accumulated in the heavy solution and, when the heavy solution falls on the turbine buckets, we add the energy of Earth’s gravity, thereby increasing the energy balance of the system and ensuring its operating cycle.