Notice

Transition is currently unavailable. Maintenance in progress.

From smooth coils to insulated pipes — precision-crafted copper tubes for modern industry.

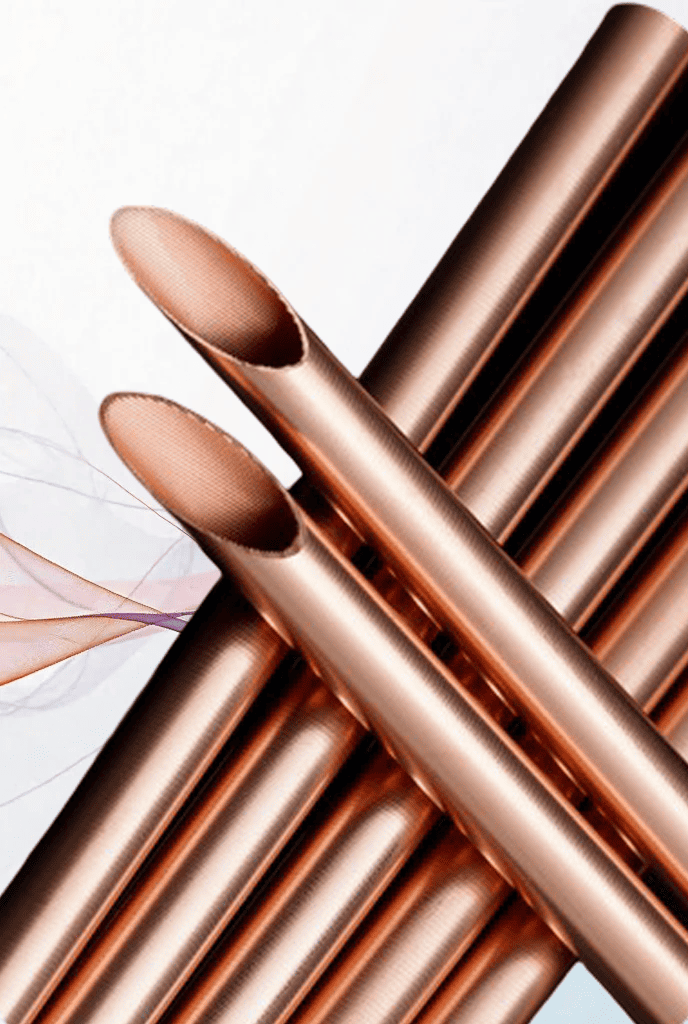

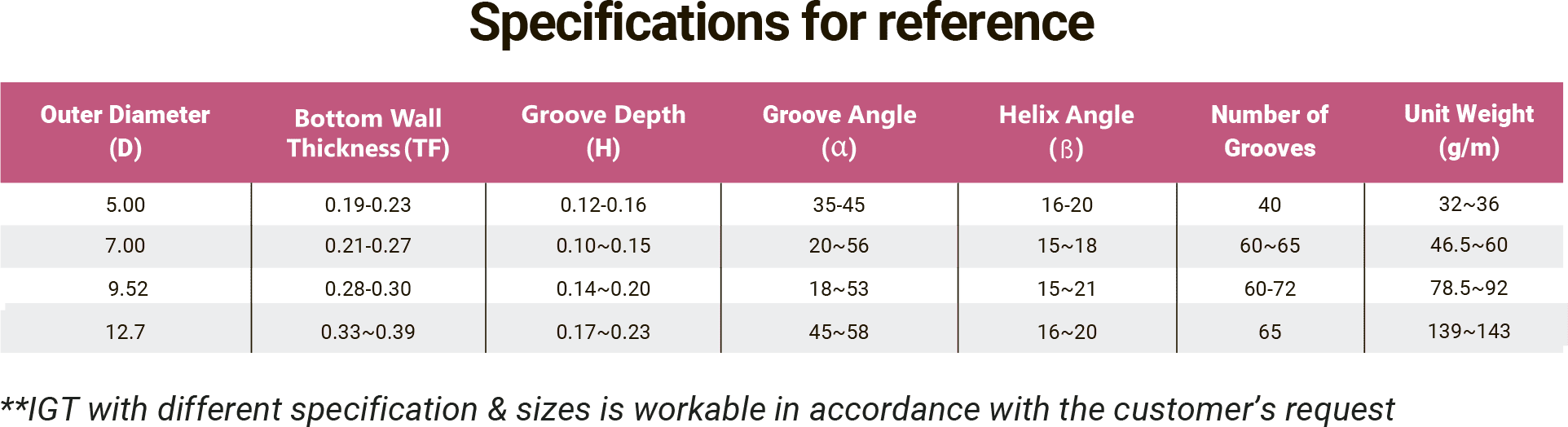

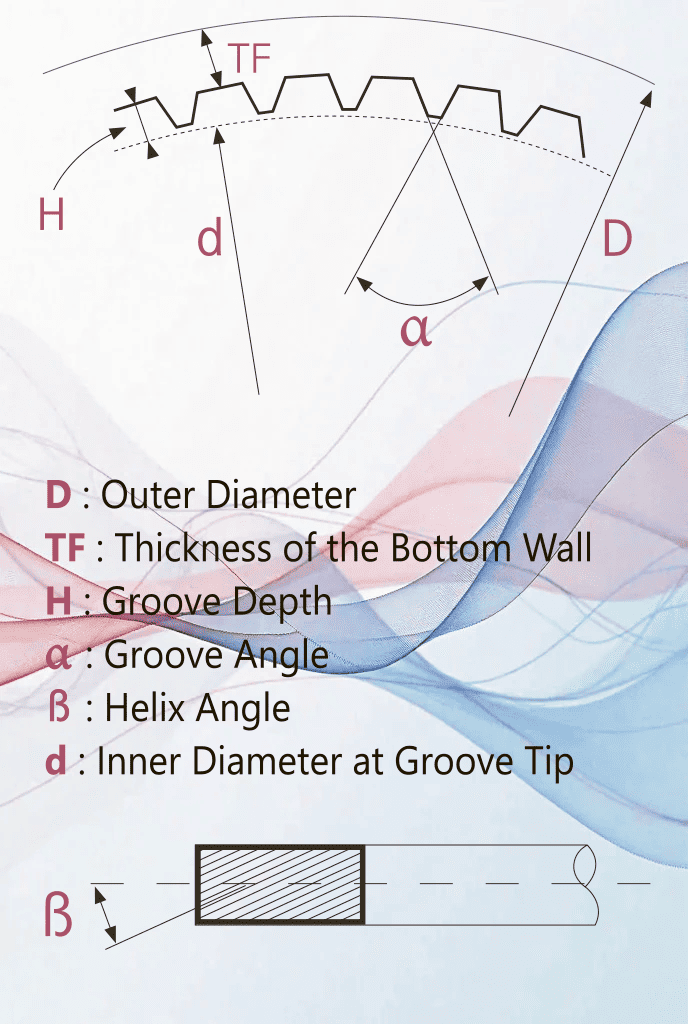

Inner-Grooved Copper Tubes are precision-engineered tubes featuring longitudinal micro-fins on their internal surface. These internal structures significantly increase the effective heat transfer area and enhance thermal exchange between the tube wall and the circulating refrigerant.

Such tubes are extensively utilised in air conditioning, refrigeration

systems, heat pumps, and other energy-efficient applications where high

thermal conductivity and compact design are required. The internal grooves

increase flow resistance, promoting fluid turbulence and thereby improving

the overall heat transfer coefficient. This results in reduced energy

consumption and improved system performance.

Manufactured from high-purity copper (minimum 99.95%), the tubes conform to

international standards including JIS, ASTM, EN, and AS/NZS. They feature

high dimensional accuracy, low weight, and excellent formability for ease

of installation. A variety of diameters and custom specifications are

available upon request.

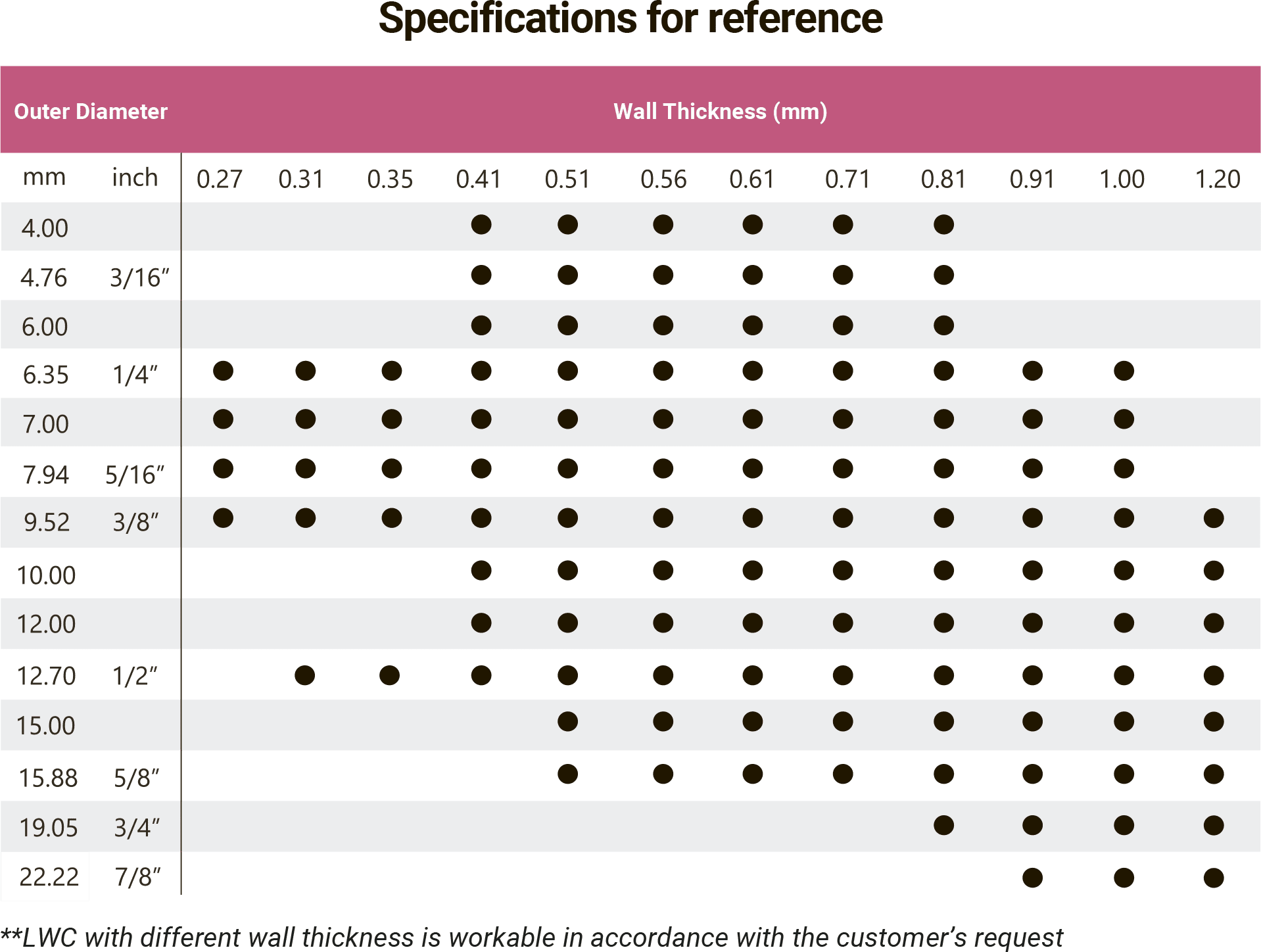

Level Wound Coils (LWC) are high-purity copper tubes (minimum 99.95% Cu),

supplied in precisely wound large-volume coils. This format enables

uninterrupted feeding in automated manufacturing processes, minimising the

need for tube splicing or manual handling.

LWC tubes are widely used in air conditioning and refrigeration systems,

as well as in heat exchangers and the broader HVAC industry. They offer

excellent dimensional accuracy, smooth surface finish, and compatibility

with high-pressure refrigerants such as R410A and R32.

Material: Copper content (Cu):minimum of 99.95%, Phosphorus concentation

(P): 0.015% - 0.04%.

The tubes are manufactured in compliance with international standards

including JIS, ASTM, EN, and AS/NZS. Available in soft (annealed) or hard

temper, they can be customised in terms of wall thickness and outer

diameter according to specific technical requirements.

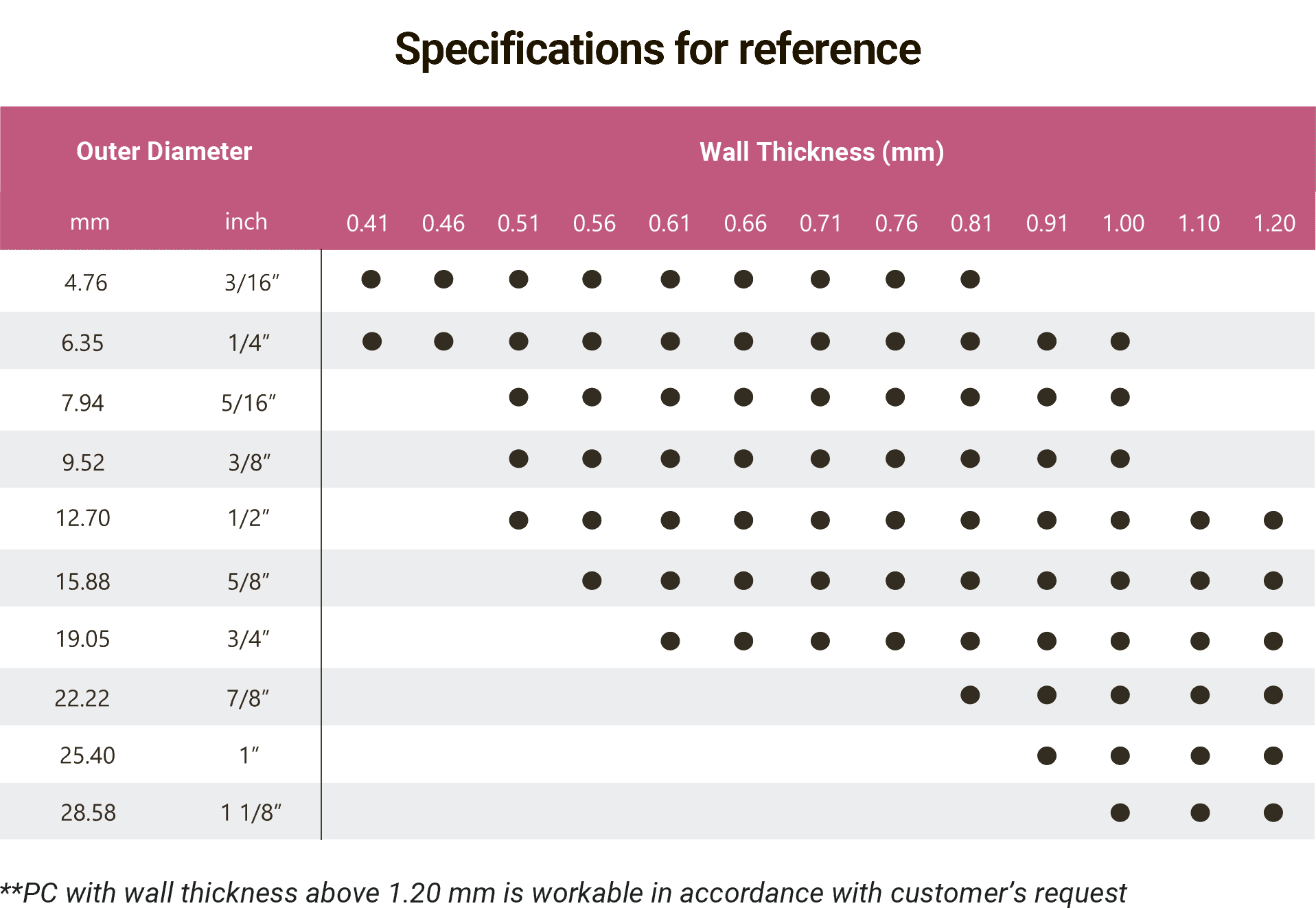

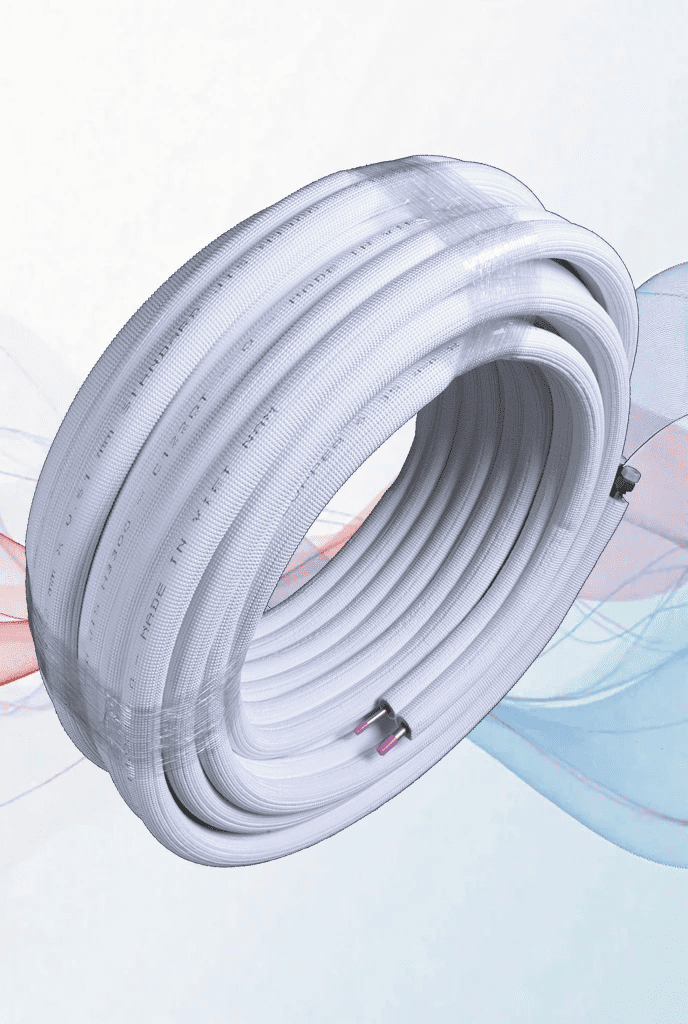

Pancake Coils are compactly wound copper tubes supplied in flat coil form,

designed for ease of transport, handling, and manual installation. They are

manufactured from high-purity copper (minimum 99.95%) with excellent

dimensional accuracy and surface quality.

These coils are widely used in both residential and commercial air

conditioning systems, refrigeration units, construction, and plumbing

applications. Pancake Coils are easy to bend and install, making them

ideal for use with high-pressure refrigerants such as R410A and R32.

The tubes feature a bright, clean surface finish, high ductility, and compliance with international standards including JIS, ASTM, EN, and AS/NZS. Standard coil lengths include 15m, 30m, 45m, and 50m with custom wall thicknesses available upon request.

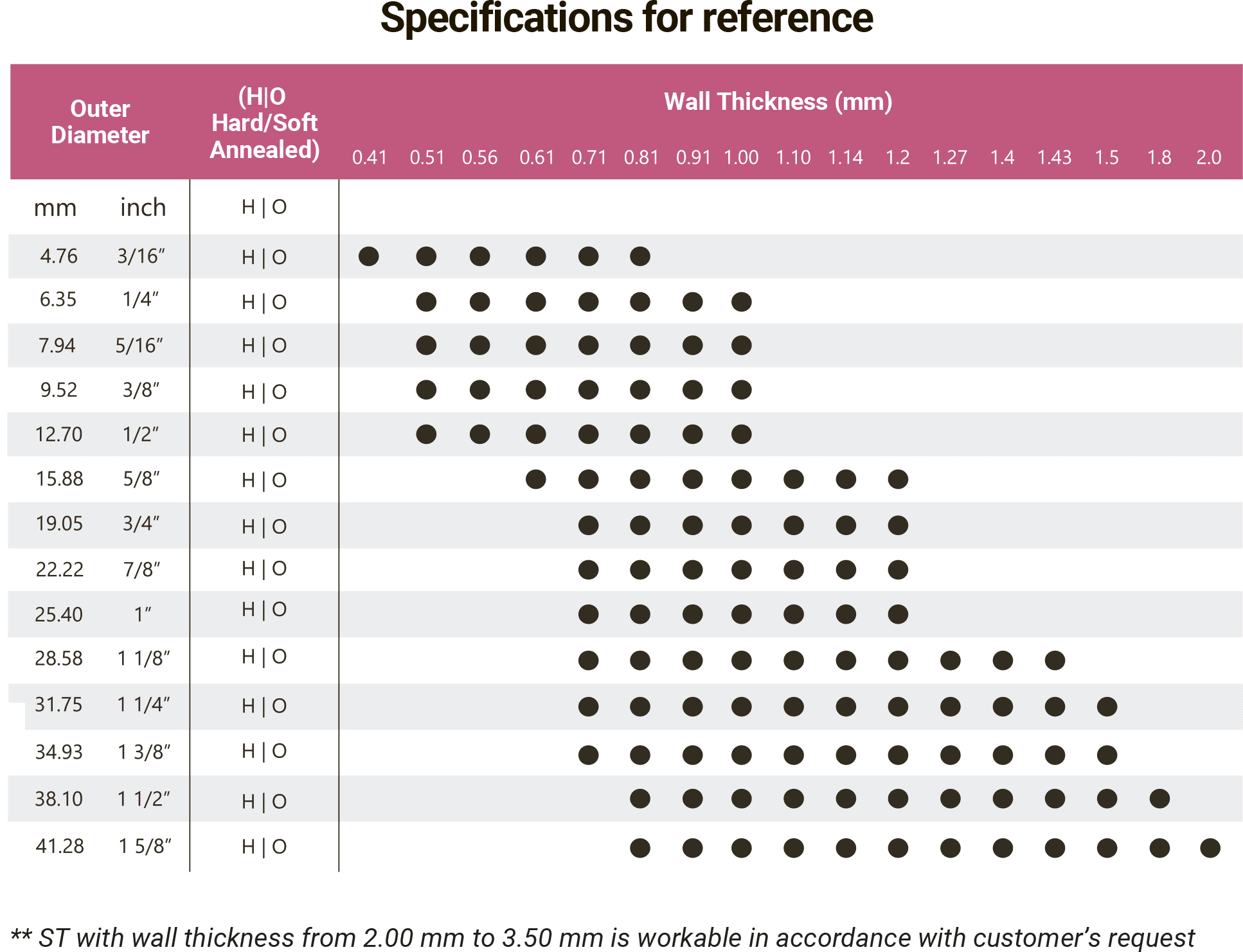

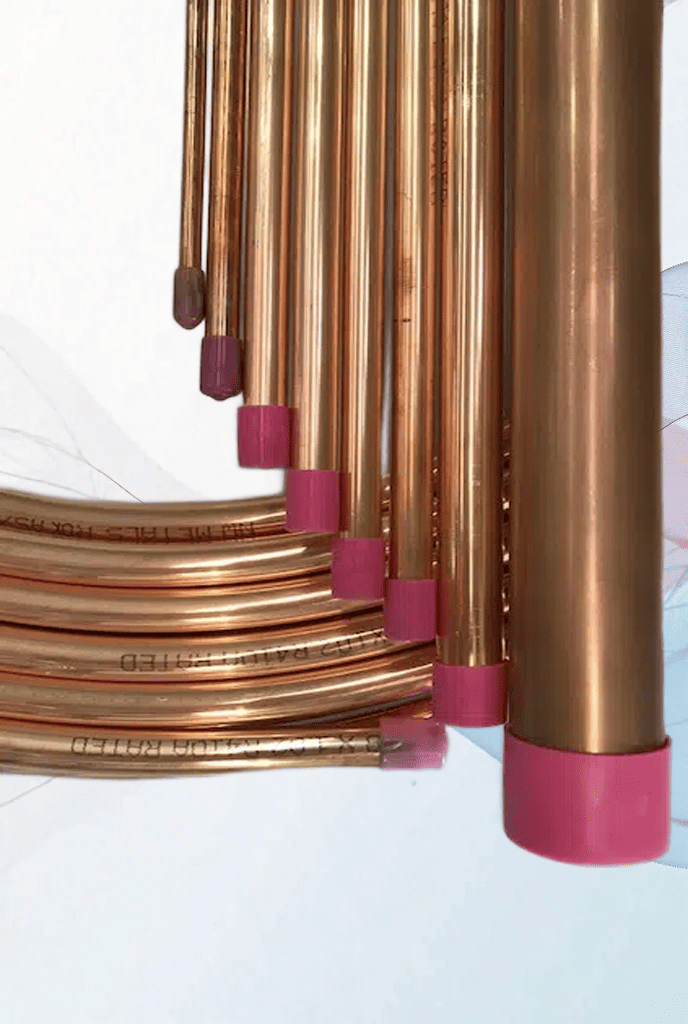

Straight Copper Tubes are precision-cut copper tube sections with a bright, smooth surface finish and excellent dimensional stability. They are widely used in HVAC systems, refrigeration, heating, construction, and plumbing applications where rigid, pressure-resistant pipework is required.

Manufactured from high-purity copper (minimum 99.95%), these tubes comply

with international standards including JIS, ASTM, EN, and AS/NZS. Straight

tubes offer excellent weldability, high internal pressure resistance, and

are available in both soft (annealed) and hard tempers depending on

application needs.

Standard length range: 2.5 metres to 6 metres, with customised wall

thicknesses and diameters available upon request.

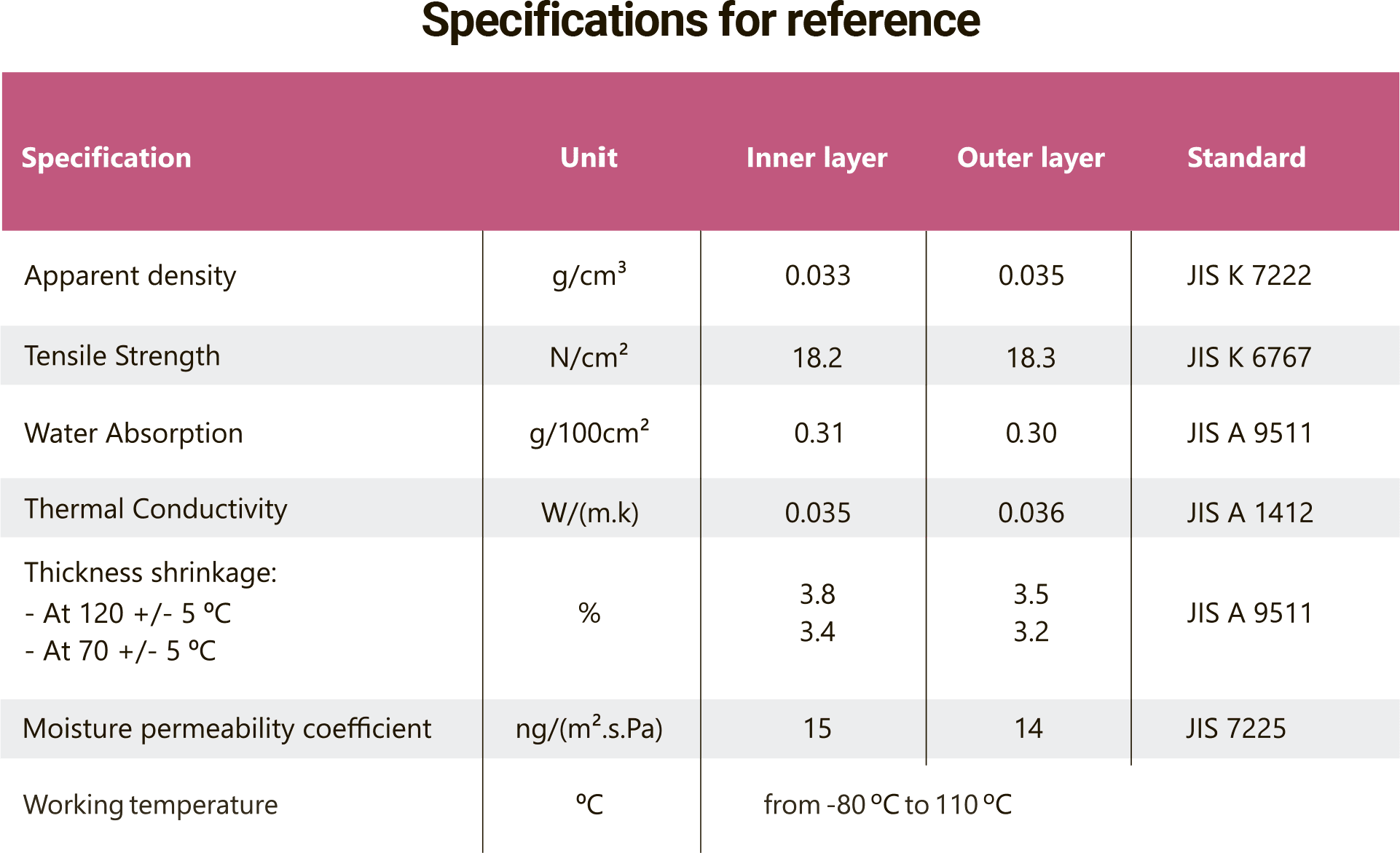

Crafted with precision, this copper coil features a premium cross-linked polyethylene insulation, meticulously expanded to form a closed-cell microcellular crystal network. A sleek, thin polyethylene outer layer envelops the insulation, delivering enhanced protection and optimised efficiency. This sophisticated combination ensures the copper tube performs exceptionally well even in the most challenging outdoor environments, making it ideal for heating, cooling, and air conditioning applications.

The coil is engineered for robust durability and impressive energy savings,

boasting outstanding resistance to mechanical pressure. Its reliable

operation spans a broad temperature range from -80°C to 110°C. Composed of

high-purity copper with a minimum of 99.95% copper content and phosphorus

levels finely balanced between 0.015% and 0.04%, this product combines

quality and performance seamlessly.

With these qualities, it effortlessly ensures energy efficiency, excellent

performance in corrosive and demanding environments, and a straightforward,

time-saving installation process — all designed to meet the rigorous

demands of modern industrial applications.

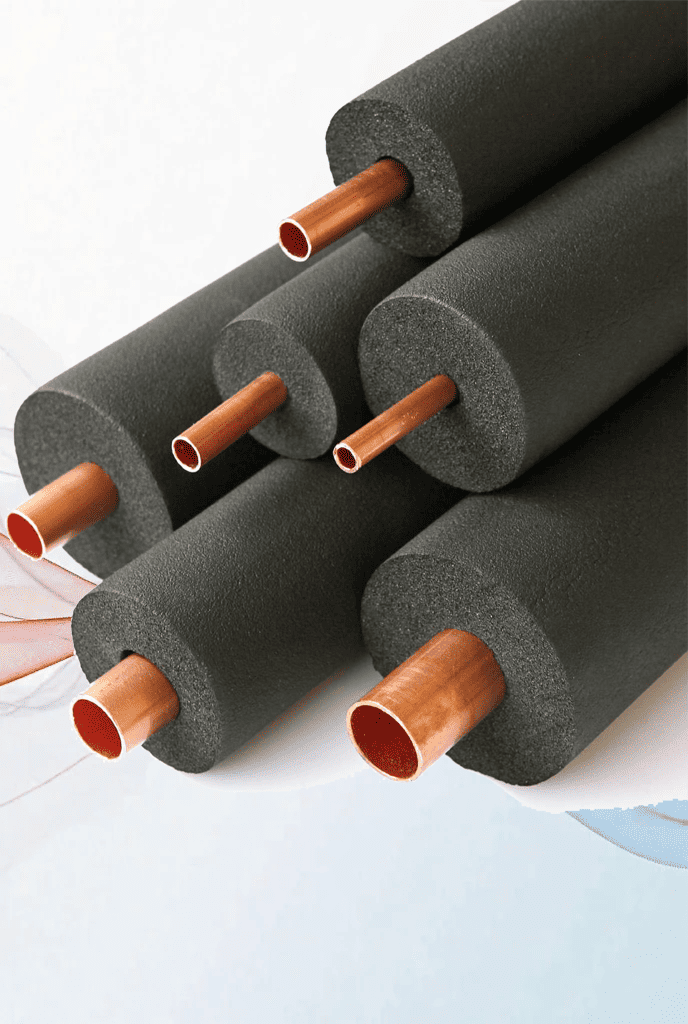

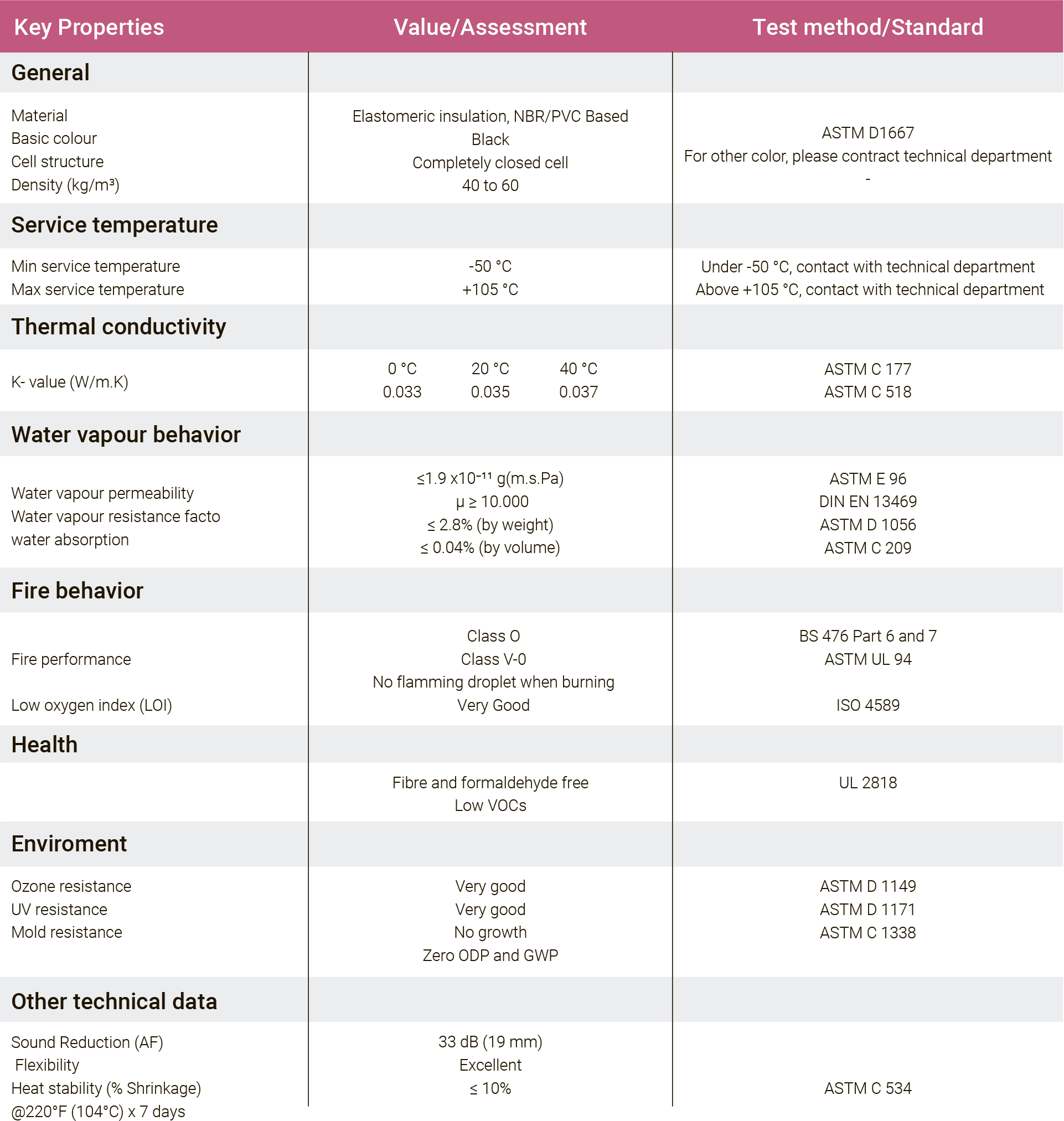

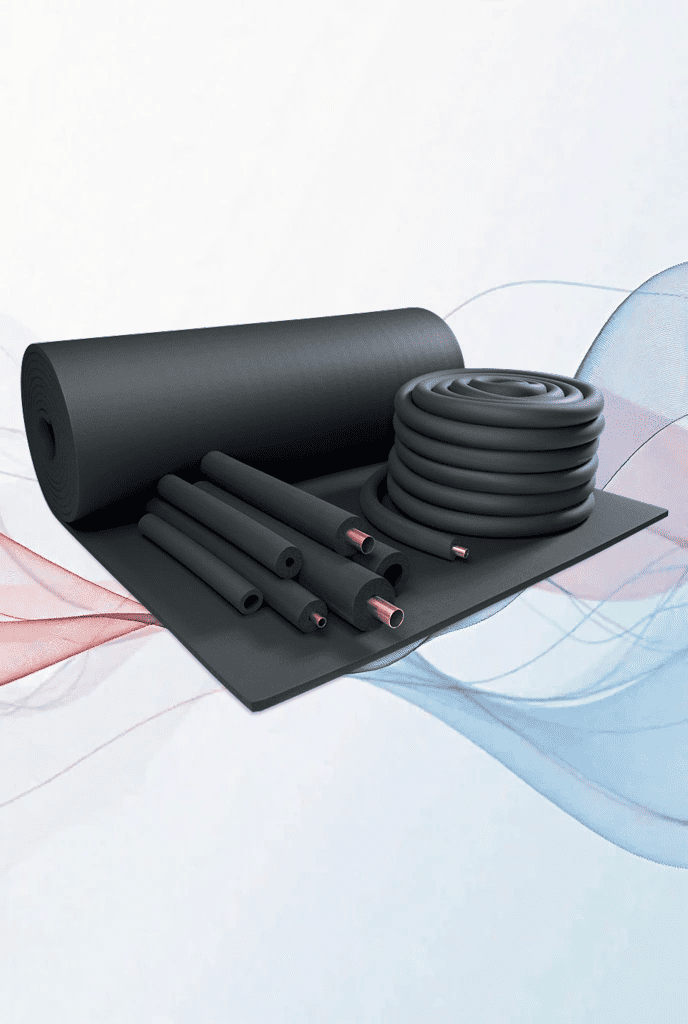

Ruby Insulation represents the pinnacle of advanced technology in thermal management. Engineered to deliver exceptional performance, it offers unparalleled energy efficiency, ensuring significant reductions in operational costs. Its robust construction provides high pressure resistance, safeguarding systems under demanding conditions. Designed with safety in mind, it ensures a secure operating environment. The insulation effectively mitigates noise, contributing to a quieter and more comfortable setting. Its durability is complemented by excellent elasticity, maintaining integrity over time. Environmentally conscious, it boasts low levels of Volatile Organic Compounds (VOCs) and high resistance to dust, aligning with sustainable practices. With low thermal conductivity—≤ 0.036 at 0°C and ≤ 0.040 at 40°C—it demonstrates superior insulating properties, particularly at elevated temperatures, making it an ideal choice for high-quality insulating foam applications.

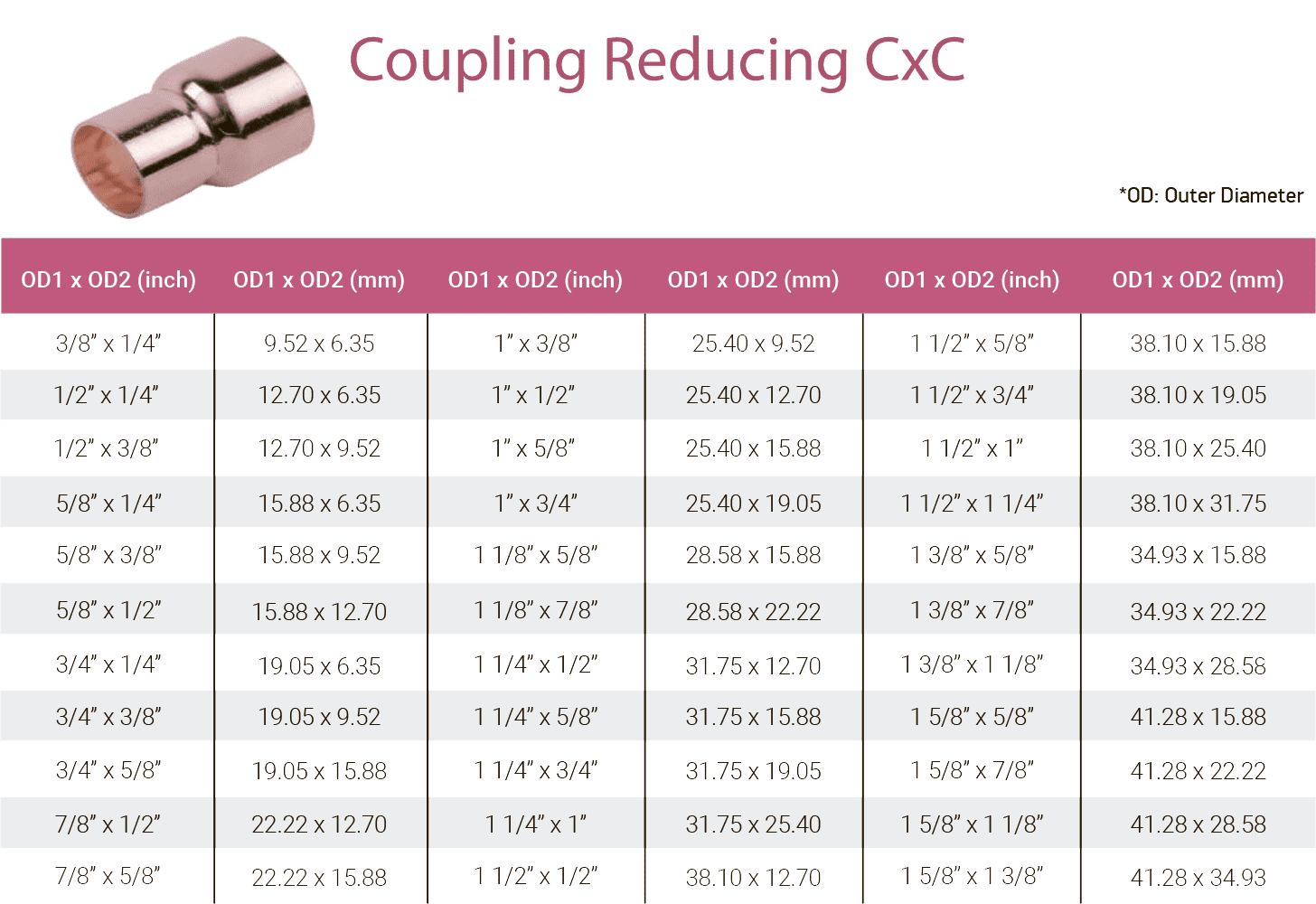

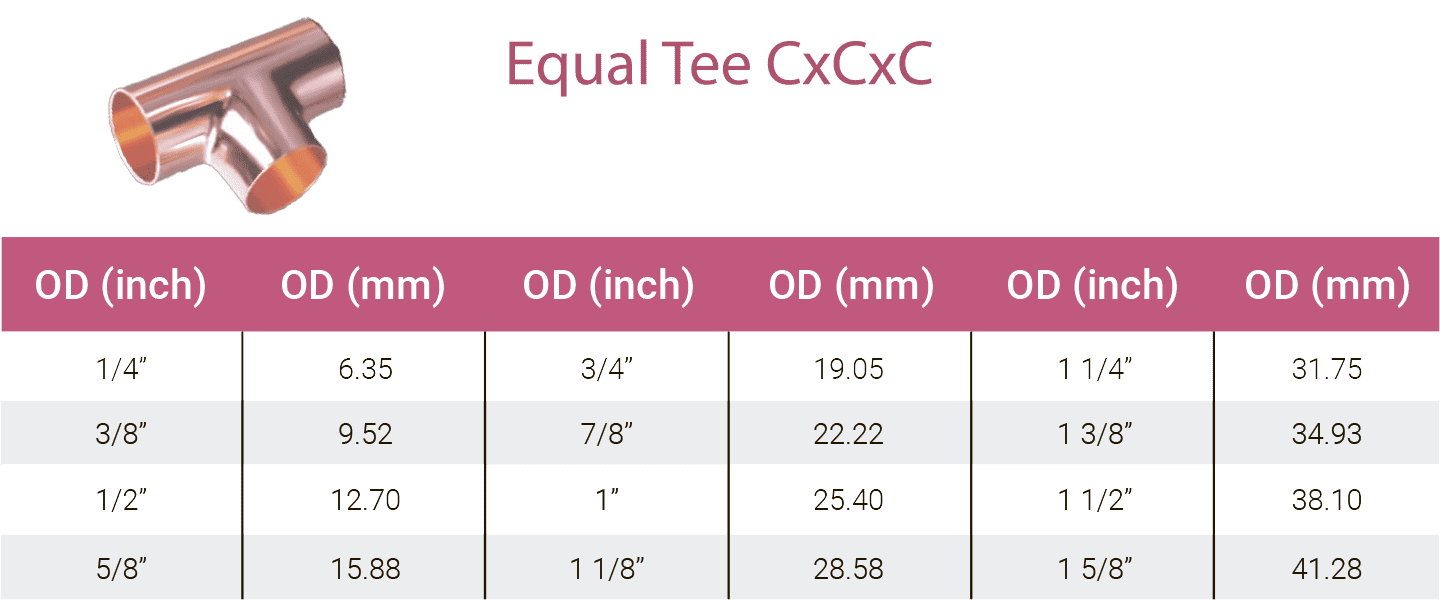

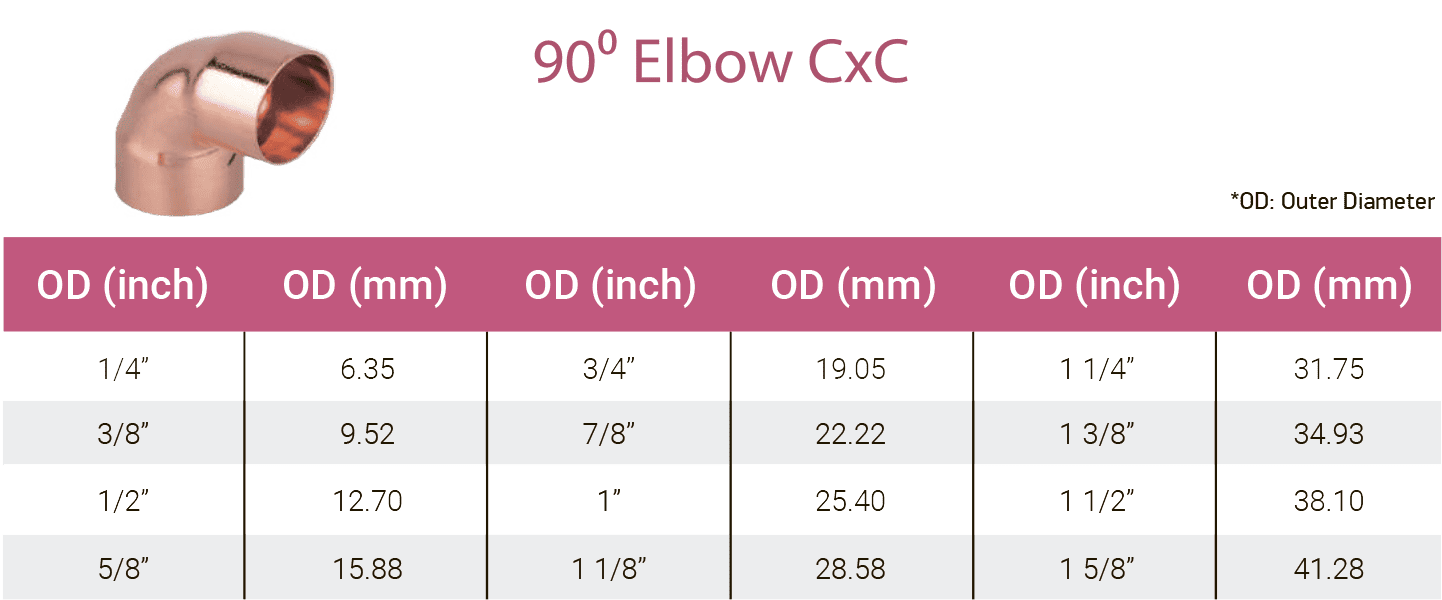

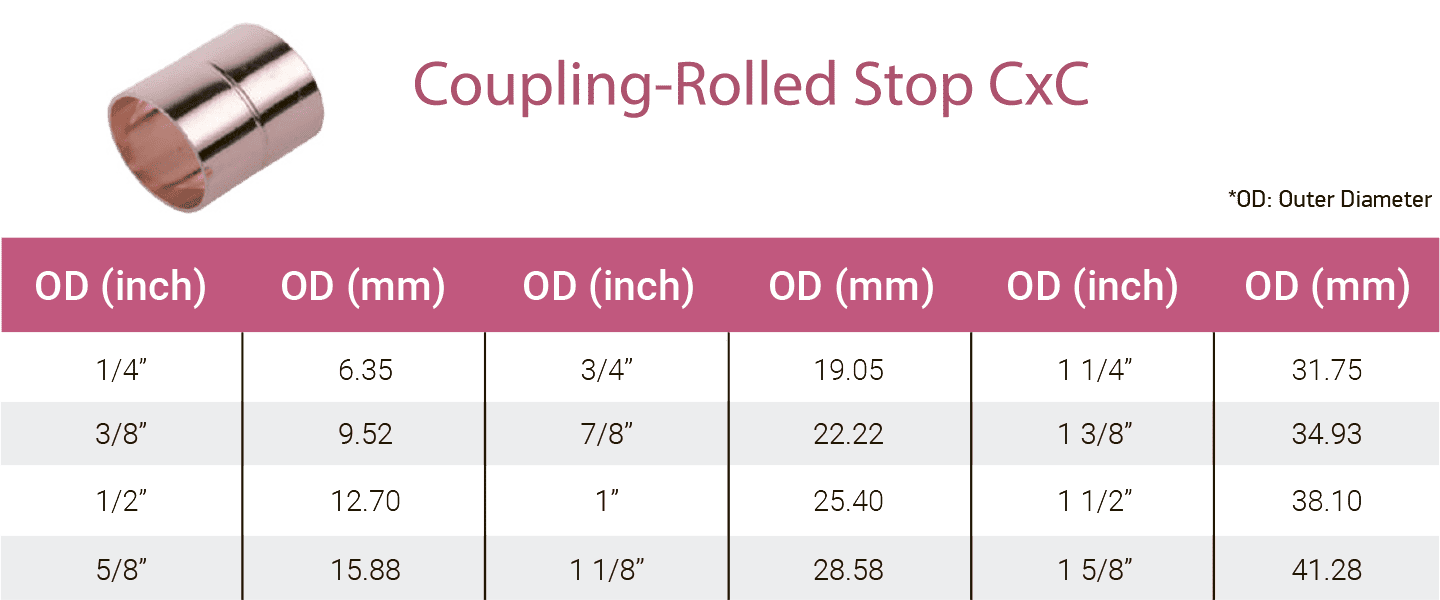

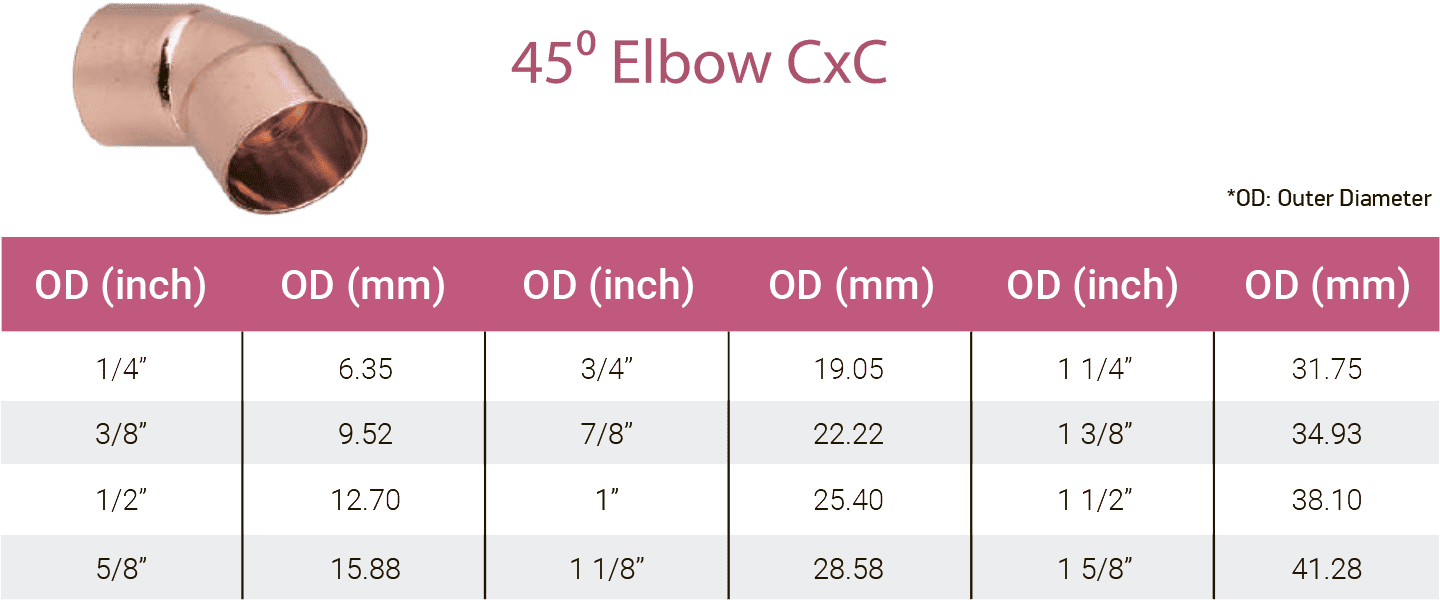

Copper Endfeed Fittings offer a reliable and efficient solution for connecting copper pipes in plumbing and heating systems. Designed for ease of installation, these fittings ensure strong, leak-proof joints that withstand high pressure and temperature variations. Crafted from high-quality copper, they provide excellent corrosion resistance and durability, making them ideal for both domestic and commercial applications. Their precision engineering guarantees a secure fit, promoting long-lasting performance and system integrity.