Notice

Transition is currently unavailable. Maintenance in progress.

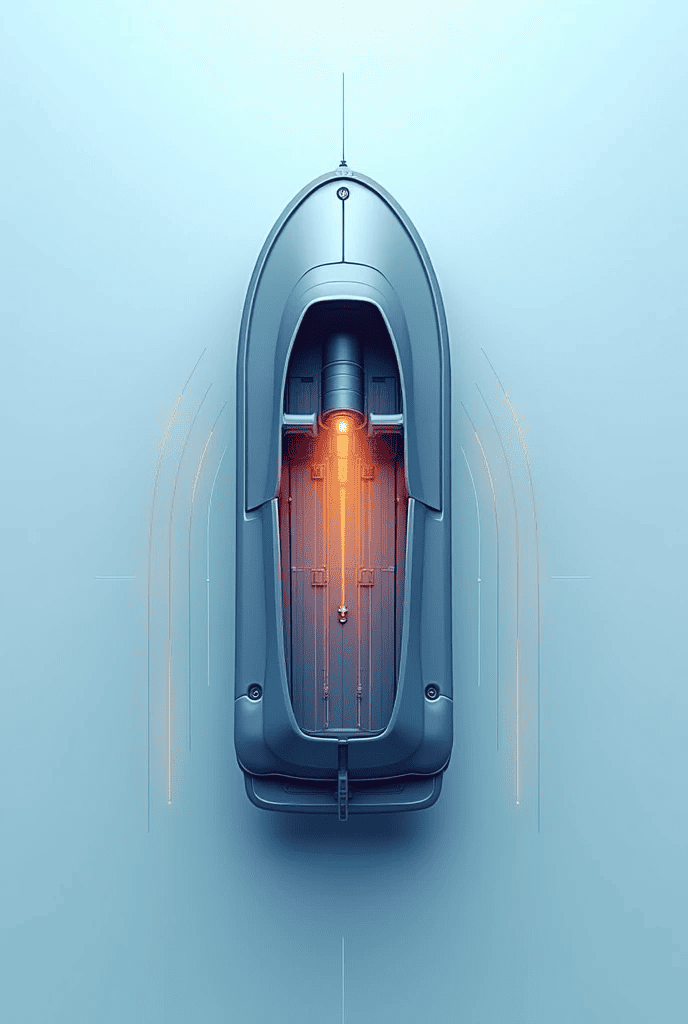

Magnetically Driven Systems for Next-Gen UAVs.

Autonomous propulsion for maritime platforms—both surface and

submersible—requires power systems that are compact, silent, and independent of

refuelling. NIMEC’s magnetic linear and rotary drive modules are specifically

engineered to meet these demands, enabling a new era in marine drone

capabilities.

Rotary magnetic modules provide stable, high-efficiency power for propellers

across a wide speed range, while linear magnetic drives can be configured as

high-speed waterjet systems. In these, thrust is generated by accelerating water

directly through magnetic field interaction, ensuring rapid response and

exceptional maneuverability with no exposed mechanical components. This is

crucial for operations in confined or hostile environments, including offshore

reconnaissance, environmental monitoring, and coastal defense.

NIMEC systems operate without combustion engines, eliminating exhaust,

vibration, and noise. This allows for low-signature deployment, undetectable by

thermal, acoustic, or visual sensors. With no fuel tanks or heat generation,

marine drones can operate safely near wildlife, within protected waters, and at

depth—free from traditional system constraints.

The modular design of the NIMEC solution enables seamless integration across a

wide range of hull forms and mission profiles, from compact survey vessels to

full-scale autonomous underwater platforms. Built-in magnetic energy generation

ensures each drone is self-sufficient, with mission duration limited only by

task requirements—not by fuel supply.

From an economic perspective, NIMEC offers a clear advantage. It eliminates fuel

costs, storage, and delivery logistics, as well as maintenance burdens

associated with combustion engines and transmission systems. There is no need

for auxiliary power sources, and the long service life of magnetic modules

ensures reliable performance with minimal upkeep—even under harsh marine

conditions. This makes the operation of maritime drones more predictable,

cost-effective, and sustainable for both civilian and defence applications.

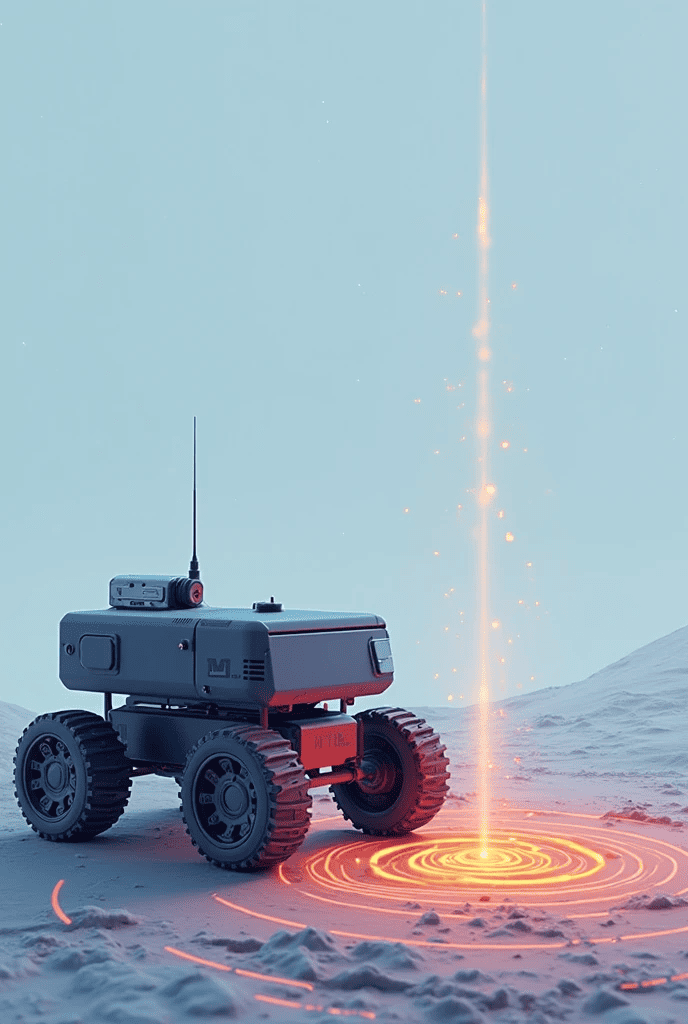

Next-generation unmanned ground platforms demand high autonomy, silent

operation, and complete energy independence. NIMEC’s magnetic drive solutions

deliver exactly that — a reliable, economical, and modular architecture. At the

core are power modules that can be seamlessly integrated into both wheeled and

tracked vehicles, enabling propulsion via electric or hydraulic motors without

the need for internal combustion engines.

The system’s energy efficiency enables not only long-range autonomous mobility,

but also supports high-energy weapons such as laser systems. These allow for

completely silent and flashless firing, with no flammable components and an

almost zero thermal signature — providing a decisive tactical advantage in

combat scenarios.

Each platform can be configured to meet mission-specific requirements. Designed

for rough terrain, swamps, or mine-infested zones where traditional mobility

fails, NIMEC-powered units can temporarily switch to low-altitude air-thrust

operation, hovering one to two metres above the ground. This capability enables

movement across complex or hazardous terrain without direct surface contact,

preserving mobility and survivability.

Maintenance and repair are simplified to the extreme: no gearbox, no internal

combustion engine, no fuel logistics. Damaged modules can be quickly replaced

in the field. The magnetic drive requires no refuelling, remains stable across

temperature extremes, and delivers continuous energy to both primary propulsion

and auxiliary systems.

Economically, these platforms are far more viable over their full lifecycle.

Eliminating fuel costs, reducing maintenance, and extending operational

longevity make the deployment of large-scale unmanned ground fleets not only

feasible but budget-stable. With NIMEC, true off-grid terrestrial mobility

becomes reality — without compromise.

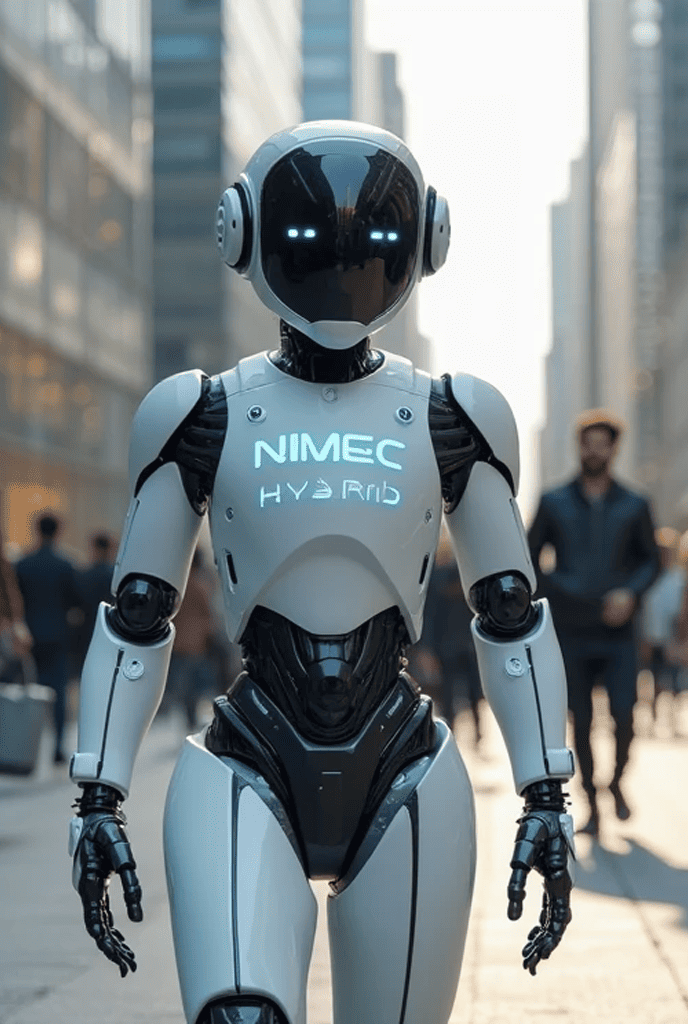

Modern robotics demands increasing autonomy, flexibility, and biomechanical

accuracy. NIMEC magnetic modules are ideally suited to meet these challenges,

providing both linear and rotational motion with high precision and controllable

response. A robot can be equipped with a single power module functioning as a

“magnetic heart” or designed with a distributed system, where each limb, sensor

array, or structural element has its own dedicated drive.

One of the key advantages lies in the ability to create flexible linear systems

that mimic the function of muscle fibres, breathing mechanics, or peristaltic

motion. This enables a new class of biomimetic machines, medical assistants,

and cybernetic exoskeletons, where movement feels organic and reaction time is

immediate and adaptive.

NIMEC modules eliminate the need for centralised transmissions, generate minimal

heat, and operate in complete silence — an essential feature for service,

medical, and reconnaissance robotics. With onboard energy generation and

integrated ultracapacitor blocks, each component functions autonomously,

reducing system load and simplifying both upgrades and field maintenance.

This architecture enhances overall reliability, minimises failure points, and

makes repairs straightforward. Instead of complex diagnostics and full-system

disassembly, a single module can be replaced — a critical advantage in

restricted or operational environments.

The NIMEC magnetic platform redefines what's possible in the development of

mobile, humanoid, and industrial robotic systems, enabling robust and effective

performance across diverse use cases — from surgical precision to post-disaster

deployment.