Notice

Transition is currently unavailable. Maintenance in progress.

Non-Contact Propulsion via Permanent Magnet Arrays.

Advances in materials science have enabled the production of industrial magnets

with extremely high magnetic energy density. Of particular importance are

compounds based on neodymium, iron, and boron, among which the tetragonal

Nd₂Fe₁₄B phase is the most studied and widely applied. These materials are

produced via powder metallurgy: rare-earth and transition metal elements

undergo sintering followed by magnetic alignment in a high-intensity field.

One of the most energetically saturated commercial grades is the NdFeB N52M

type. Its remanent magnetic induction reaches 1.48 T, coercive force is at least

836 kA/m, and maximum magnetic energy product exceeds 390 kJ/m³. The "M"

designation indicates an allowable operating temperature up to 100°C, at which

the stated parameters are retained. These characteristics make magnets of this

class benchmark components in applied and research tasks requiring compact yet

powerful and stable magnetic field sources.

The development and serial production of high-energy NdFeB magnets, particularly

the N52M type, have enabled precise engineering control of magnetic interactions.

This has driven the creation of new designs and models across several

technological fields. Notably, the use of such magnets underpins applied

magnetic research conducted by entities including the NIMEC research division.

The production of modern permanent magnets is based on a technological process

involving powder preparation, sintering, and magnetic alignment within a strong

external magnetic field. During these operations, a significant amount of energy

is introduced and fixed within the magnet, which then manifests as a magnetic

field.

The energy required to create a permanent magnet is spent on altering the

internal structure of the material, organising magnetic domains, and overcoming

energy barriers, resulting in a stable magnetised state. Thus, a permanent

magnet represents an energy-saturated system, analogous to a battery or

accumulator, capable of retaining the stored energy for extended periods.

This fact justifies considering permanent magnets as energy devices with

accumulated energy, enabling precise quantitative accounting and modelling of

magnetic interaction processes, similarly to calculations used for

electrochemical accumulators.

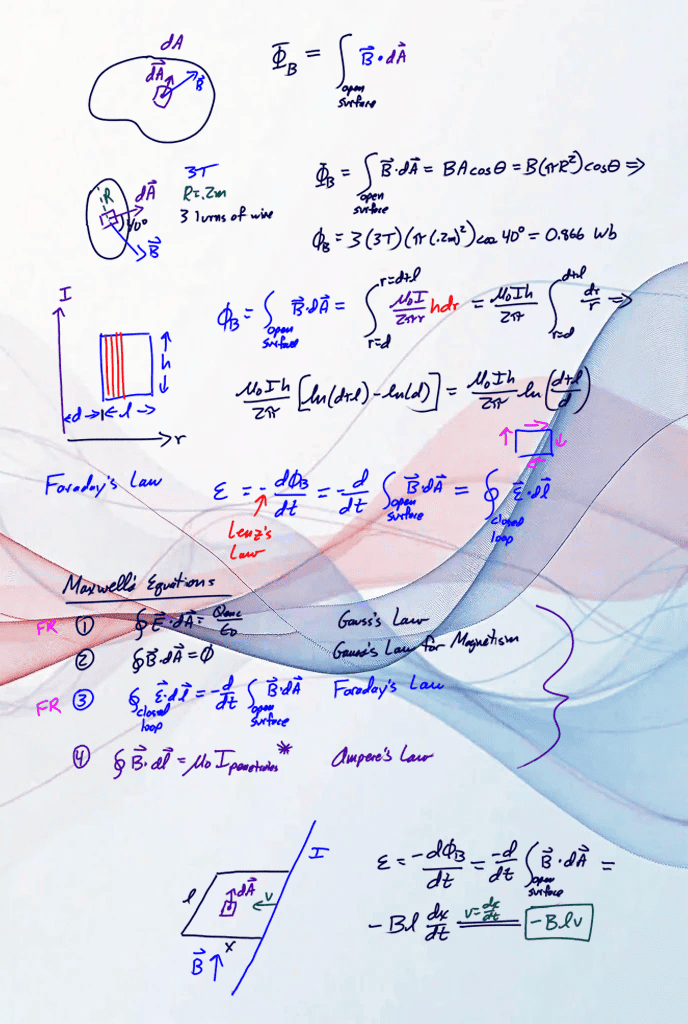

The physical nature of magnetic fields lends itself to quantitative description

through a set of well-defined parameters. Among the most fundamental are

magnetic flux density (B), magnetic field strength (H), magnetic flux, and the

magnetic permeability of the medium.

Magnetic flux density (B) is a vector quantity that characterises the strength

of a magnetic field in terms of the force it exerts on moving electric charges

and magnetic materials. It is measured in tesla (T). Instruments such as

gaussmeters and vector magnetometers are used for its measurement.

Magnetic field strength (H) describes the intensity of a magnetic field

generated by electric currents and magnetic dipoles within a material. It is

measured in amperes per metre (A/m) and typically determined using Helmholtz

coils and current probes calibrated for spatial field distribution analysis.

Magnetic flux is defined as the product of magnetic flux density and the area it

penetrates, and is measured in webers (Wb). Magnetic permeability, in turn,

reflects a medium’s ability to conduct magnetic flux and is expressed in henries

per metre (H/m).

The development of accurate measurement techniques for these quantities has

made it possible to formalise magnetic interactions and establish a mathematical

basis for their modelling. Calculations based on the finite element method (FEM)

accommodate complex geometries, nonlinear material properties, and spatial

current distributions. Among the most advanced software platforms used in this

domain are COMSOL Multiphysics and ANSYS Maxwell, which enable detailed dynamic

modelling of magnetic systems.

Access to precise parameters, specialised instruments, and reliable

computational tools has transformed magnetic field analysis from a descriptive

discipline into a predictive engineering practice. Permanent magnets are no

longer abstract sources of force; they have become controllable components

within engineered systems. As a result, in contemporary machines and mechanisms,

permanent magnets are employed as active functional elements — on par with

energy sources, control modules, and actuators.

The formalisation of the physical parameters of magnetic fields, the advancement

of measurement techniques, and the introduction of reliable modelling tools have

enabled a transition from descriptive observation of magnetic interactions to

their purposeful engineering application. Modern permanent magnets are now

regarded as functional components of technical systems, characterised by

predictable properties and high energy density.

The most significant area of application is in electric power generation. In

such generators, the magnetic flux is established without the need for external

excitation current, leading to a simplified construction, reduced thermal

losses, and improved energy efficiency. The use of neodymium-iron-boron (NdFeB)

based materials—particularly those of the N52M grade—enables high flux densities

to be achieved within compact dimensions while maintaining operational stability

under thermal and mechanical stress.

In brushless electric motors (BLDC, PMSM), permanent magnets act as stable

sources of magnetic flux in the rotor. This configuration eliminates the need

for moving electrical contacts, thereby improving reliability and controllability.

These motors are widely used in drones, electric vehicles, servo drives, and

compact traction systems, including hub motors. The high coercive stability of

modern magnets ensures consistent performance even under varying external

conditions.

In both household and industrial applications, permanent magnets are utilised in

the drives of pumps, fans, and compressors, as well as in acoustic systems and

sensors. The long-term stability of their magnetic properties ensures reliable

operation with minimal maintenance requirements over extended service periods.

In medical technology, magnets are applied in devices for magnetic therapy, in

systems for magnetic navigation of microrobots, and in magnetic resonance

imaging (MRI). In the latter, field stability in both space and time is

critical—a requirement that can only be met by high-energy permanent magnets

with tightly controlled material properties.

In measurement technology, magnets form integral parts of Hall effect sensors,

magnetoresistive elements, and magnetic positioning systems. Their compactness

and lack of power consumption make them particularly suitable for use in

telecommunications equipment, security systems, and precision instrumentation.

Thus, permanent magnets are not merely auxiliary components but key structural

elements of modern technical systems. Their properties are not only accounted

for in design processes, but actively define both the limitations and

capabilities of the system as a whole. This elevates the magnet to the status

of an active engineering tool—on par with power sources, control electronics,

and mechanical assemblies.

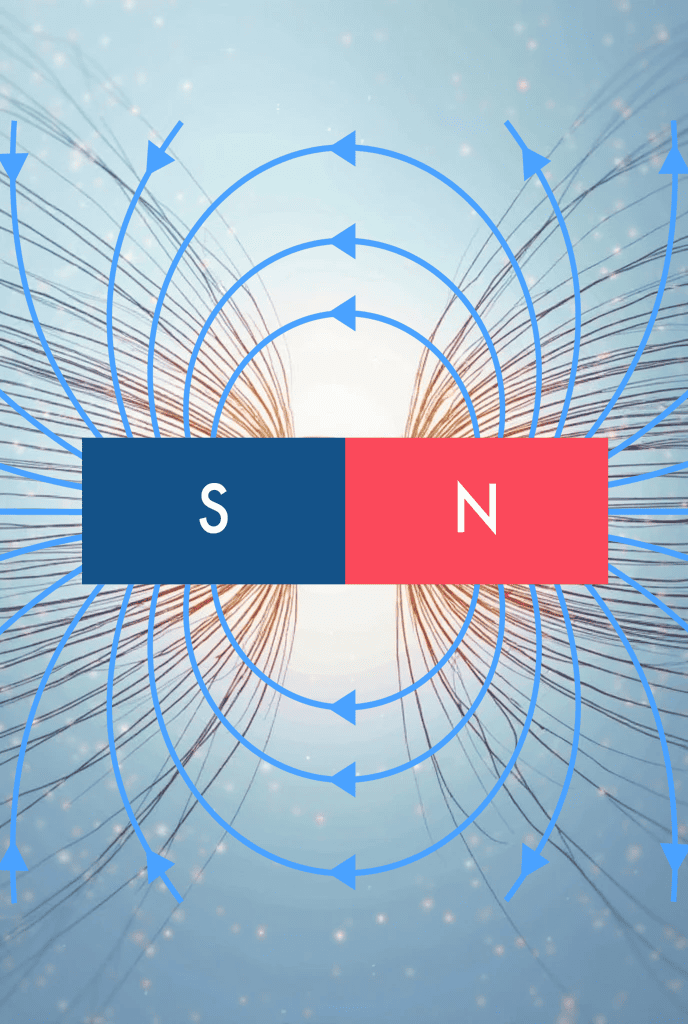

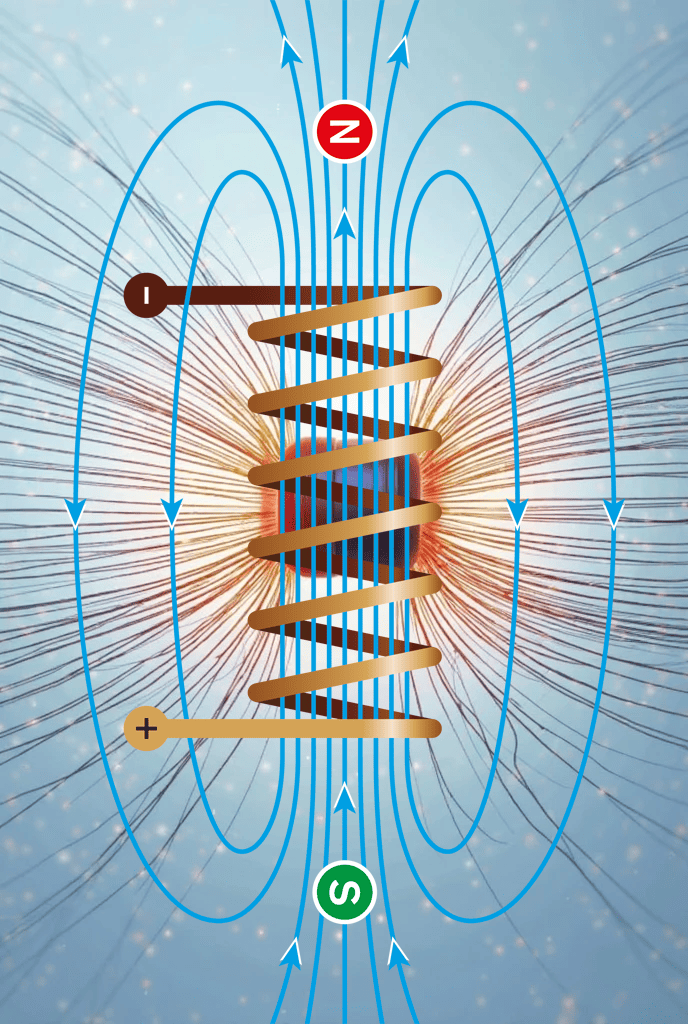

Magnetic interactions are based on a fundamental principle of polarity, which

determines the direction of forces of attraction and repulsion between magnets.

Each magnet has two poles — north (N) and south (S) — and the interaction

between them follows the rule: like poles repel, unlike poles attract.

Although simple, this rule underlies complex magnetic systems and defines the

nature of mutual forces in magnetic arrays. The magnitude and direction of the

force depend on the orientation of the poles relative to each other and the

distance between them. The force is inversely proportional to the square of the

distance, reflecting Coulomb’s law as applied to magnetic forces.

Understanding and applying the principle of magnetic polarity is key to

designing systems that require precise control of magnetic forces, such as

motors, generators, and magnetic couplings. Without consideration of polarity,

stable and efficient operation of magnetic devices is impossible.

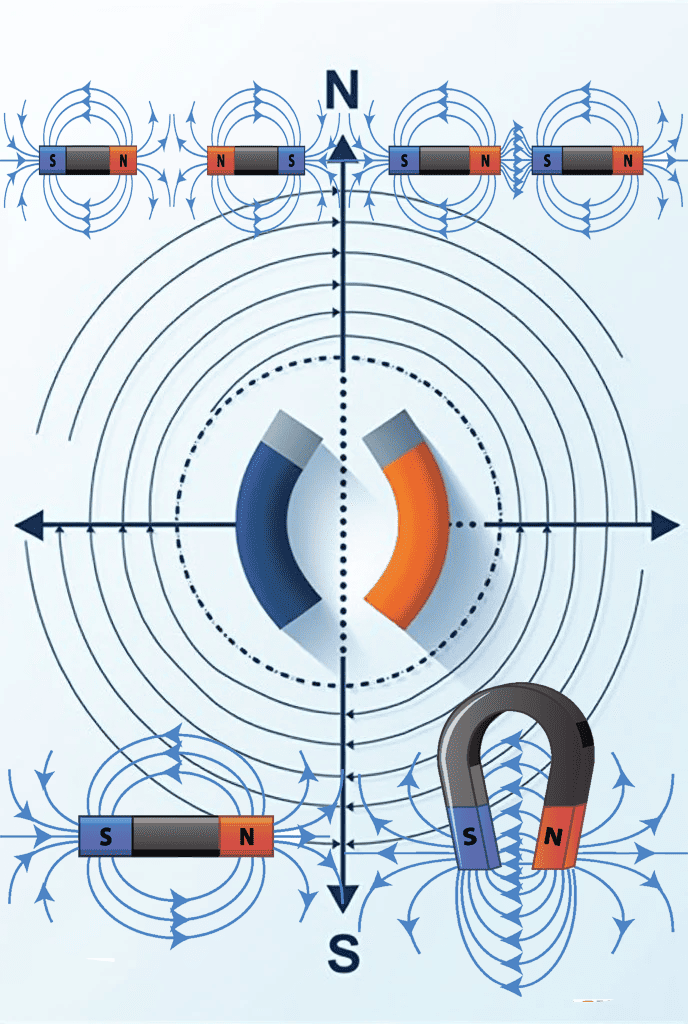

The interaction of magnetic fields is fundamentally influenced by the spatial

configuration of the magnets — their shape, orientation, and relative

positioning. These parameters determine not only the magnitude but also the

nature of the magnetic interaction, affecting the distribution of the magnetic

field in space.

The shape of the magnets — whether cylindrical, prismatic, ring-shaped, or

complex composite structures — defines local field characteristics and creates

zones of varying magnetic intensity. The distance between magnets influences

the force of attraction or repulsion, with the force diminishing rapidly as

distance increases, in accordance with the inverse-square law.

Furthermore, the orientation of the poles relative to one another and the

angles between magnets can significantly alter the nature of the interaction,

producing complex effects employed in engineering applications for precise

control of motion, fixation, and force transmission without physical contact.

Therefore, understanding and accounting for the spatial configuration of

magnetic systems enables the design of efficient and controllable magnetic

devices, thereby expanding the scope of permanent magnet applications in modern

technologies.

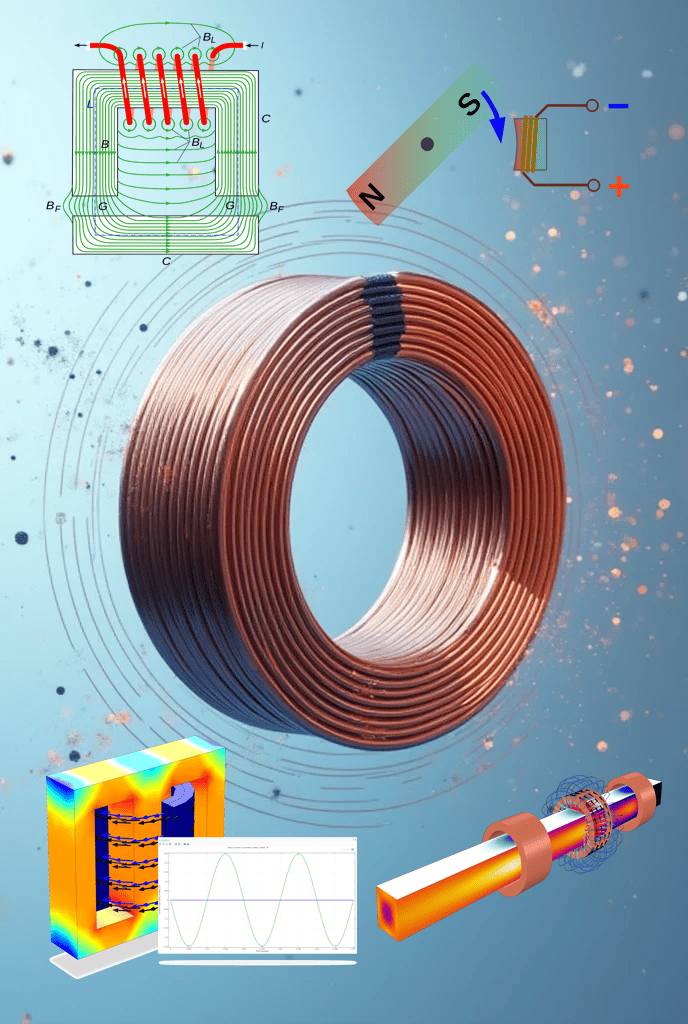

The magnitude of the field is proportional to both the current and the number

of coil turns. However, increasing the current leads to greater thermal stress

in the coil, resulting in additional energy losses. Therefore, the energy

efficiency of an electromagnet is limited by the ratio between the required

field strength and the acceptable level of power consumption.

To achieve a high field intensity, either the current must be increased or the

magnetic circuit must include materials with high permeability. Both approaches

influence the design volume and thermal management of the device.

The key parameters defining electromagnet characteristics include the number of

coil turns (N), the current (I), the magnetic path length (l), the core

cross-sectional area (S), and the magnetic reluctance (Rₘ), which depends on

the material and geometry of the system.

Electromagnets are employed where a controllable field is required: they can be

switched on, off, or adjusted without mechanical modification. This

controllability makes them essential components in systems for actuation,

control, power conversion, and magnetic separation.

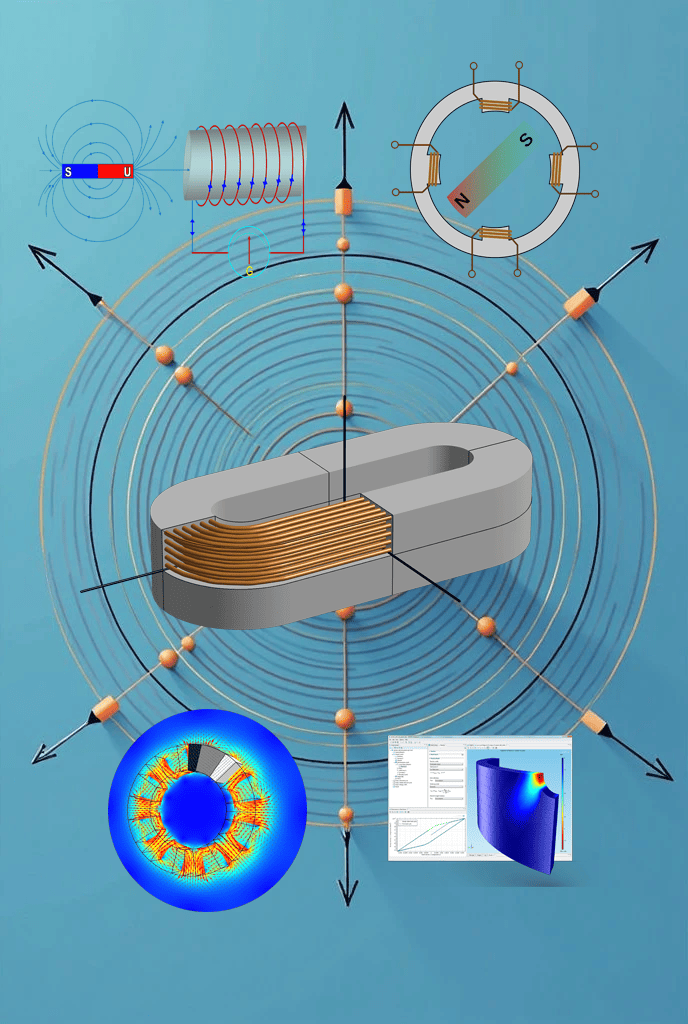

The combination of permanent magnets and electromagnetic windings is widely

employed in modern electrical machines, particularly in permanent magnet

synchronous motors (PMSMs). This configuration leverages the benefits of both

magnetic sources: the stability and high flux density provided by permanent

magnets, and the controllability and dynamic performance enabled by

electromagnetically generated fields.

The permanent magnet establishes the primary magnetic field in the air gap of

the machine, supplying rotor magnetisation without the need for external

excitation. This significantly reduces energy consumption, as no excitation

current is required and a portion of the mechanical load is offset from the

active windings.

The stator’s electromagnetic windings generate a rotating field that interacts

synchronously with the rotor’s field. This interaction results in high

efficiency and precise torque control. The higher the magnetic induction

produced by the permanent magnet, the lower the current needed to generate the

desired torque, directly reducing thermal losses and improving overall system

efficiency.

With the use of high-coercivity materials such as NdFeB of class N52M, high

magnetic flux density can be achieved within a compact volume. This facilitates

simplified motor integration and extends the operational range of the system.

Such combined magnetic configurations are particularly effective in traction

drives, drones, automation systems, and electric vehicles, where compactness,

reliability, and low energy losses are of critical importance.

The original concept proposed by Nikola Tesla in the late 19th century involved

a commutated system of four energy storage elements connected in such a way

that the current induced in a coil by the motion of a permanent magnet would

not be dissipated but redirected to charge other components within the circuit.

In such configurations, the coil simultaneously functions as both an

electromagnet and a generator. When excited by a moving permanent magnet, it

produces an induced current which, in most conventional designs, is either

grounded or actively suppressed.

Tesla’s innovation lay in his proposal to utilise this induced current to

alternately charge capacitors, thereby partially offsetting the energy required

to sustain the magnetic field. In its classical implementation, switching was

performed mechanically and constrained by the technological limitations of the

time.

With the advent of modern graphene-based supercapacitors, this concept has

gained renewed practical relevance. These energy storage devices exhibit high

current density, low internal resistance, and an exceptional ability to absorb

charge rapidly. Unlike traditional capacitors, graphene supercapacitors are

well-suited to capturing short bursts of current generated as a permanent

magnet moves relative to a coil.

Owing to these properties, a modern reinterpretation of Tesla’s switch no

longer depends on high switching frequencies. Rapid charging combined with

controlled, gradual discharge enables energy-efficient use of the electrodynamic

interactions intrinsic to the system. As a result, a portion of the energy

previously lost as heat or through grounding can now be recovered and reused

within the circuit, or diverted to auxiliary subsystems.

This contemporary implementation of Tesla’s concept, enabled by advances in

materials science, remains fully consistent with established physical

principles while offering engineers a means of improving energy balance in

systems involving dynamic magnetic fields. It elevates a historical invention

to a viable and efficient design strategy for next-generation autonomous drive

systems.

Modern demands for compactness, energy efficiency, and thermal stability in

electromagnetic devices have driven the adoption of advanced materials in both

core and structural components of coils. The choice and combination of these

materials play a critical role in determining the performance and reliability

of devices in industrial environments.

For magnetic cores, alloys with high magnetic permeability and saturation

induction are increasingly utilised. One such material is Permendur—an

iron-cobalt-vanadium alloy (Fe-Co-V)—which offers saturation induction values

up to 2.4 T and low core losses under high-frequency conditions. Due to its

high coercive stability and thermal resilience, Permendur is particularly

effective in devices subjected to variable thermal and mechanical loads. Its

use enables a reduction in core volume while maintaining the required magnetic

induction, thereby decreasing the overall weight and size of the assembly.

In parallel with advances in core materials, structural design solutions are

evolving. The widespread application of 3D printing with polymeric and

composite materials—tailored for specific dielectric and mechanical

properties—facilitates the fabrication of coil housings and supports with high

dimensional precision. This enables optimisation of magnetic system geometry,

reduction of inter-winding gaps, and an increase in winding density. Adapting

the enclosure geometry to the magnetic field configuration reduces parasitic

losses and promotes more uniform heat distribution.

Special attention is given to conductive materials. Advances in electrolytic

copper production have lowered the cost of high-purity conductors. The use of

99.99% pure copper reduces ohmic losses and allows for higher current capacity

without increasing conductor cross-section. This is especially critical for

windings operating under pulsed conditions or in thermally constrained

environments.

The integration of these innovations allows the construction of electromagnets

with higher magnetic energy density, reduced mass and volume, and improved

thermal stability. The application of novel materials and manufacturing

techniques not only enhances device efficiency but also supports adaptation

to emerging functional requirements in energy systems, transportation, and

automation.

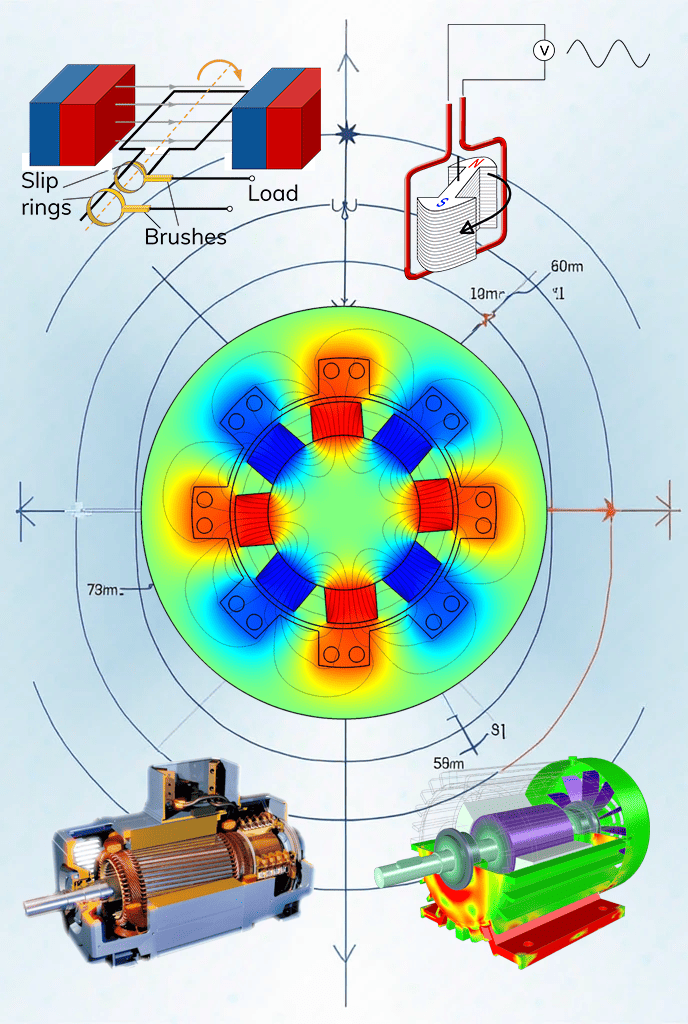

Electric motors are devices in which magnetic field energy is converted into

mechanical work through the interaction between electric current and magnetic

flux. Regardless of the specific construction, all motors operate on the same

fundamental physical principles: the force acting on a current-carrying

conductor in a magnetic field (Ampère’s law) and the phenomenon of

electromagnetic induction (Faraday’s law).

The core of any motor is its electromagnetic system, which generates the working

magnetic field. The interaction between this field and the current in the

windings produces a torque, the magnitude of which depends on the current

strength, field configuration, and geometric arrangement. Most motor designs

incorporate ferromagnetic cores to concentrate and guide the magnetic flux,

thereby reducing energy losses.

The performance of an electric motor is determined by the parameters of its

magnetic circuit: magnetic induction, field intensity, air gap dimensions, and

the properties of the materials used. Magnetic interaction thus forms the

fundamental physical basis for rotational motion, and the control of this

interaction is central to engineering optimisation.

Permanent magnet electric motors (BLDC, PMSM) exhibit high energy efficiency,

resulting in lower power consumption while delivering comparable mechanical

performance relative to conventional brushed motors.

For example, the brushless ATO-180WDM16030 motor, rated at 5 kW with a supply

voltage of 48 V and a current of 123 A, provides a nominal torque of 16 Nm and

a peak torque of up to 42 Nm. In contrast, the traditional Lynch LEM-170 brushed

motor, operating at the same voltage of 48 V but with a higher current of 140 A,

produces a nominal torque of approximately 14.4 Nm and a peak torque around 16.2

Nm.

Despite the higher current in the brushed motor, its peak torque is

significantly lower than that of the ATO brushless motor. Furthermore, the

BLDC motor achieves an efficiency of up to 98%, compared to 89% for the brushed

counterpart. The higher efficiency and lower current demand of the BLDC motor

translate into reduced energy consumption and decreased thermal losses.

The absence of brushes reduces mechanical losses and wear, while the use of

permanent magnets in the rotor eliminates the energy expenditure required to

generate the magnetic field, further enhancing overall efficiency.

Therefore, permanent magnet motors enable maximisation of torque output with

optimised energy consumption, which is particularly crucial in

energy-constrained applications such as drones, electric vehicles, and mobile

robotics.

Permanent magnets have found widespread use in electric motors and generators,

becoming an integral part of modern technological solutions. These devices have

undergone extensive development and testing, proving their reliability,

efficiency, and durability across a wide range of fields — from industrial

manufacturing to consumer electronics. Particularly important are magnets based

on neodymium-iron-boron (NdFeB) alloys, which today are the standard in most

high-performance electromagnetic systems due to their high magnetic energy and

stability.

The use of permanent magnets in motors and generators reduces energy

consumption, decreases the mass and size of equipment, and simplifies design by

eliminating the need to power rotor windings. All this contributes to the

creation of compact, powerful, and economical solutions that are in demand in

modern industry.

These technologies have stood the test of time and operational use, as evidenced

by their widespread application in aviation, automotive engineering, robotics,

and energy sectors. The reliability and efficiency of permanent magnets in

electrical engineering are the result of many years of research and engineering

achievements, integrated into standardised manufacturing processes.

Mathematical modelling of magnetic fields has become an essential tool in the

development and optimisation of electromagnetic devices. Modern software

packages enable highly accurate predictions of magnetic field distribution,

calculation of force characteristics, and assessment of system behaviour under

various operating conditions.

Modelling technologies significantly reduce the time and cost of prototyping,

allowing the exploration of design and material options at the early stages of

development. These tools help engineers identify bottlenecks, optimise the

geometry of coils and cores, and predict the efficiency and heating of

equipment.

Widely used methods include finite element analysis, boundary element methods,

and integral equations, providing precise numerical solutions for complex

magnetic systems. Validation of modelling results against experimental data

confirms the reliability and applicability of contemporary computational

techniques.

Thus, the capability for mathematical modelling of magnetic fields paves the

way for the creation of highly efficient and innovative electromagnetic devices,

ensuring their stable and predictable operation.

NIMEC does not utilise untested materials or experimental components. Its

innovations are not based on altering the physical foundations of

electromechanics, but rather on the advanced engineering integration of

well-established and thoroughly validated principles. NIMEC reinterprets

the interaction between electromagnets and permanent magnets by drawing upon

the collective scientific knowledge accumulated over decades, applying it in

novel configurations of connection and control.

Unlike conventional permanent magnet motors, in which electromagnets operate

continuously and therefore consume energy at all times, NIMEC employs a pulsed

operational mode. Electromagnets are activated only when a change in the

system’s state is required; at all other times, energy consumption is

effectively zero. This strategy results in a substantial reduction in power

usage without compromising mechanical performance.

During the inactive phase of the electromagnet, rotation is sustained through

the attractive force between the permanent magnet and the ferromagnetic core,

which serves as an energy reservoir via the magnetic field. The motor’s

structural design enables mechanical advantage by increasing the rotor diameter.

Magnetic attraction acting at a greater radius produces higher torque, thereby

exploiting the principle of leverage to enhance output force without raising

energy consumption.

During the inactive phase of the electromagnet, rotation is sustained through

the attractive force between the permanent magnet and the ferromagnetic core,

which serves as an energy reservoir via the magnetic field. The motor’s

structural design enables mechanical advantage by increasing the rotor diameter.

Magnetic attraction acting at a greater radius produces higher torque, thereby

exploiting the principle of leverage to enhance output force without raising

energy consumption.

The company further implements concepts originally proposed by Nikola

Tesla—particularly the idea of a switching mechanism whereby the coil of the

electromagnet, during its interaction with the permanent magnet, functions not

only as an actuator but also as a generator. In standard designs, the induced

current from this interaction is typically grounded and wasted. In contrast,

NIMEC captures this current and directs it to recharge energy storage units.

This approach allows for the recovery and reuse of transient energy impulses,

maximising overall efficiency.

For energy storage, NIMEC utilises advanced graphene-based supercapacitors

capable of accepting charge within fractions of a second while maintaining a

prolonged, stable discharge. Their use significantly extends the system’s

autonomous operational period without requiring external recharging.

In summary, NIMEC does not promise speculative or theoretical solutions.

Rather, it delivers a rigorously engineered system that combines time-tested

physical principles with cutting-edge technology. The result is a highly

energy-efficient, long-lasting, and mechanically reliable platform—one

grounded not in conjecture, but in physics and demonstrable engineering logic.

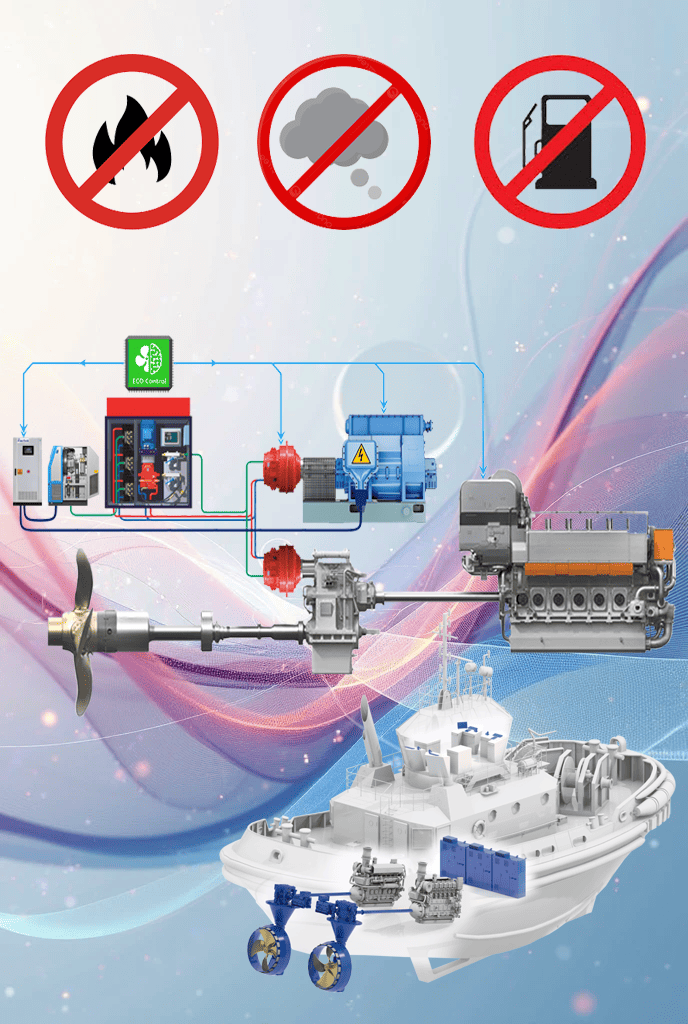

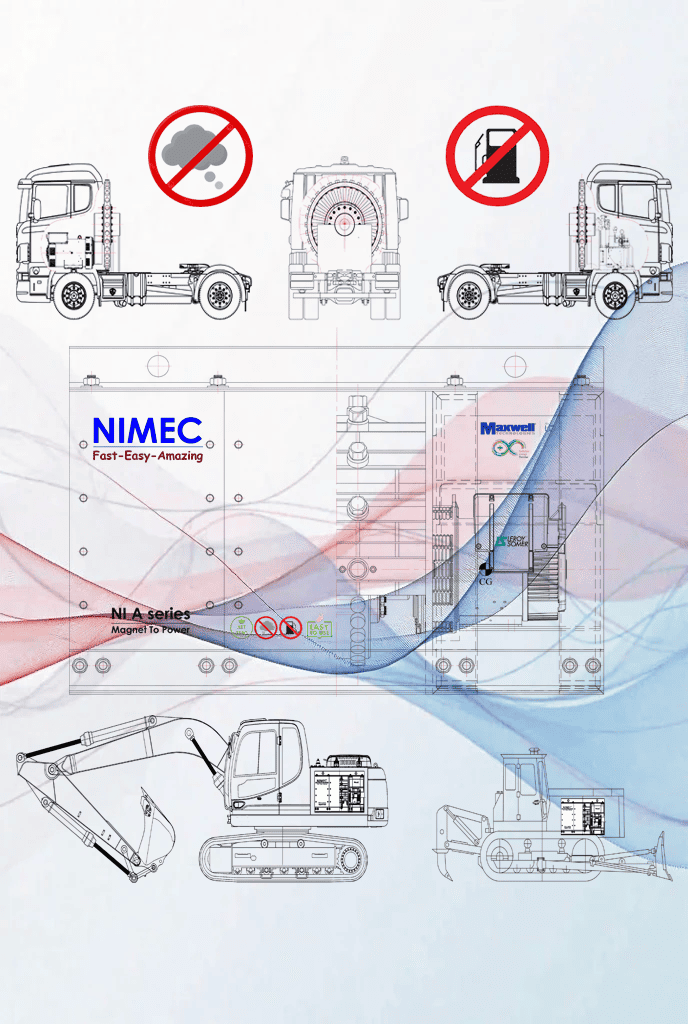

NIMEC has developed an efficient concept that integrates its ultra-low-energy

electromagnetic drive with hydraulic systems. By employing a pulsed

electromagnetic motor supported by permanent magnets acting as energy

accumulators, the system significantly reduces electrical power consumption

without compromising performance.

This motor drives a hydraulic pump, generating fluid flow at the required

pressure and volume. The resulting hydraulic energy is then distributed to

actuating components—hydraulic motors capable of producing both linear and

rotational motion. These hydraulic motors can be applied to drive marine

propellers, power the tracks of tracked vehicles, rotate wheels in automotive

systems, or operate heavy-duty industrial machinery.

In this configuration, permanent magnets serve not only to generate torque but

also function as passive energy reservoirs. This approach eliminates the need

for fossil fuel-based propulsion, offering a highly efficient, cost-effective,

and environmentally sustainable solution.

By integrating NIMEC’s electromagnetic drive with hydraulic architecture, a new

class of energy systems emerges—suitable for both mobile and stationary

applications—that is technically robust, environmentally responsible, and

economically viable.

NIMEC has developed an efficient integration scheme combining a magnetic motor

with electric generators, utilising the energy stored in strong permanent

magnets as a compact and stable energy reservoir. In this configuration, the

magnetic field serves not only as a source of force, but also as the basis for

converting stored magnetic energy into useful mechanical work.

Thanks to the unique construction of the NIMEC motor—based on pulsed control

and precise interaction between electromagnets and permanent magnets—rotational

motion of the rotor is achieved with minimal energy losses. This rotation is

then transmitted to the shaft of an electric generator, effectively

transforming mechanical energy into electrical output.

The system demonstrates particularly high efficiency when paired with modern

permanent magnet synchronous generators (PMSGs), which—due to the absence of

excitation windings and their inherently high efficiency—form an ideal match

for the NIMEC motor. This configuration enables the creation of compact and

reliable energy units capable of producing stable electricity even under

limited power supply and low start-up current conditions.

Such a combination opens the path to highly efficient autonomous power systems,

where the magnetic field itself acts as the energy medium, and both the motor

and generator operate in a harmonised and balanced configuration. NIMEC’s

solution represents a significant advancement in sustainable energy

engineering, bringing together physically validated principles with

cutting-edge system design.

A distinctive place in NIMEC’s technological portfolio is occupied by

next-generation linear actuation systems based on the interaction between

permanent magnets and paired electromagnets. The system consists of a movable

permanent magnet positioned along an axis between two opposing electromagnets.

Control is managed via the NIMEC T Smart Switch — an intelligent commutation

unit that sequentially activates the electromagnets, generating directional

force and inducing linear motion of the magnet.

This magnet is mechanically linked to piston rods of hydraulic or pneumatic

cylinders, converting the linear displacement into fluid pressure and

circulation. The result is a closed-loop system capable of producing

mechanical work without reliance on fossil fuels and with exceptionally

low energy consumption. Due to the high efficiency of magnetic interaction

and the impulse-mode operation of the electromagnets, the system achieves

remarkable energy savings while maintaining robust output performance.

The compactness of this design enables seamless integration into autonomous

mobile platforms — from robotics to lightweight aerial drones. When paired

with flexible cylinders and adaptive materials, the system can mimic biological

muscle function, accurately replicating contraction and relaxation cycles.

This positions NIMEC’s linear drives as a promising technology for the

development of soft, bioinspired motion systems within the next generation of

self-sufficient machines.