Notice

Transition is currently unavailable. Maintenance in progress.

Closed-Cycle Hydro Modules Powered by Magnetic Drive.

NIMEC proudly presents the world’s first modular power station as

Container-Based Power technology! This innovative system is a fully

autonomous electricity generation station, assembled from six High Cube 40-foot

containers. The station is delivered in a Plug & Play format — all you need is

a levelled site. Our specialists will handle delivery, installation, and

commissioning of the equipment on a turnkey basis.

We use a Pelton turbine because it is one of the most efficient impulse-type

hydraulic turbines, perfectly suited for high-head liquid applications. It

transforms the kinetic energy of a powerful jet into rotational mechanical

energy with minimal losses. The high-pressure jet is directed through a nozzle

and strikes the specially designed buckets arranged around the turbine wheel.

Thanks to the unique shape of the buckets, the liquid is redirected by nearly

180°, enabling maximum energy transfer and producing a strong torque.

In our station, we employ a heavy liquid — an 70% solution of zinc iodide

(ZnI₂, CAS 10139-47-6) — chosen for its high density. This innovative solution

allows for the most effective utilization of the Earth’s gravitational field,

converting it efficiently into mechanical shaft rotation. By feeding the heavy

liquid onto the Pelton turbine buckets from above, we have achieved outstanding

system efficiency. This liquid is completely environmentally safe, circulating

within a closed and sealed loop, ensuring sterile operation and significantly

extending the service life of the equipment. Moreover, using a heavy liquid

significantly reduces the volume needed compared to traditional water-based

solutions, simplifying the system and lowering operational costs.

The reduced volume of heavy liquid and the use of modern materials allowed us

to employ high-speed hydro- and pneumatic cylinders. These cylinders efficiently

receive energy from compressed air and transfer it to the heavy liquid,

maintaining continuous circulation. Powerful compressors compress the air,

which also circulates within a closed-loop system, maintaining constant air

quality essential for long-term reliable compressor operation. The sealed

circulation of both liquid and air ensures the station’s autonomy and stable

operation, regardless of environmental conditions.

We utilize permanent magnet generators, which offer a high efficiency rate by

eliminating the need for external excitation — the magnetic field is created by

the magnets themselves. This reduces energy losses, simplifies the design,

minimizes heating and mechanical wear. As a result, our generators operate more

quietly, reliably, and efficiently, and have a longer lifespan compared to

traditional electric machines. By using permanent magnet generators, we can

transform almost 100% of mechanical energy into electrical energy with minimal

losses.

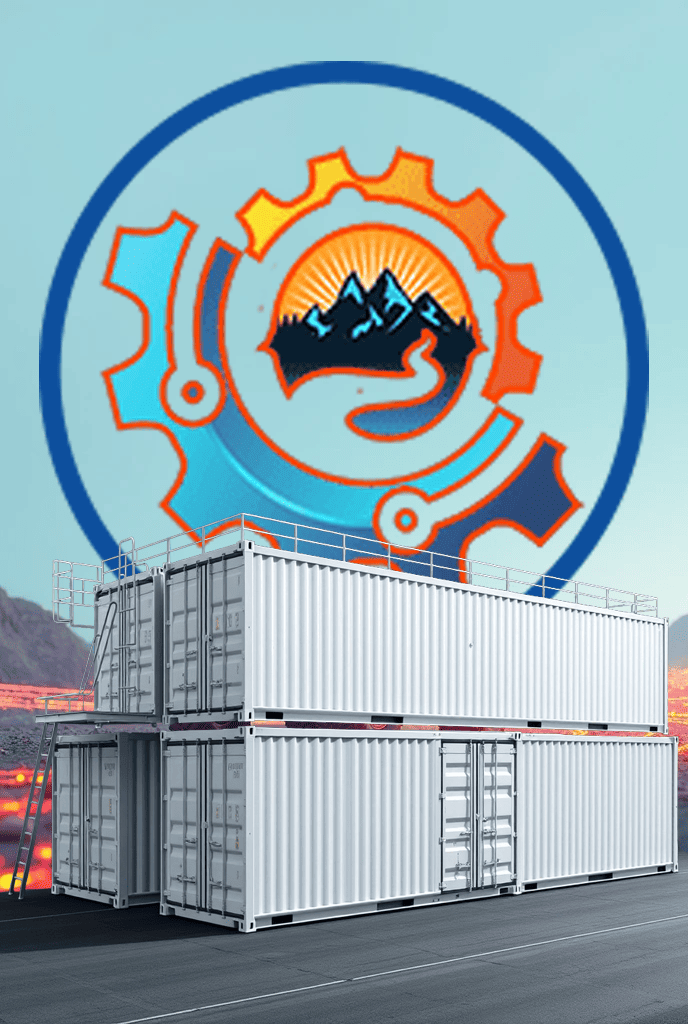

The module consists of six containers arranged in two horizontal rows. Vertical

support columns are installed between and at the ends of the containers,

forming a structural frame that provides overall rigidity. Attached to the

columns are three levels of service platforms: the first positioned 200 mm above

ground level, the second aligned with the top of the lower container row, and

the third aligned with the top of the upper row. These platforms provide access

for maintenance personnel.

The containers are equipped with side and end doors to ensure convenient access.

All blocks are fitted with fire suppression systems, remote control units, and

emergency stop functions. The system can be started or stopped either locally

or remotely.

The system is delivered as a set of eight 40-foot High Cube containers. Two of

these containers are used to house components and assemblies that could not be

accommodated within the six primary containers. After installation and

commissioning of the module, these auxiliary containers may be removed from the

site or repurposed as a separate technical unit according to customer

requirements.

Between the two containers of the lower row is a central container housing two

sets of 180 cylinders each. The cylinders are used to process a heavy liquid

(a 70% zinc iodide solution), which flows into them without pressure after

exiting the Pelton turbine and is then directed to the impulse node accumulator,

rated for a maximum pressure of 350 bar. Two linear pipelines extend from the

accumulator to the Pelton turbine’s impulse system. The container also houses

pipelines for supplying inert gas (nitrogen) at 450 bar and discharging it at

12 bar, along with local lines for feeding and draining liquid from the

cylinder groups.

On one side of the central container in the lower row is a container for inert gas

storage and supply. It includes two high-pressure compressors, each driven by a NIMEC

magnetic motor of appropriate capacity; a gas receiver rated to 15 bar; and twelve

50-litre cylinders pressurised to 300 bar for inert gas storage. Each compressor is

equipped with a controller, safety assemblies, and a gas conditioning unit. The

cylinders serve to initiate the circulation system and supply the fire suppression

unit. They feature external refueling ports and safety blocks, allowing gas refilling

without entering the container.

On the opposite side of the central container is a container housing a local

control room with an external communication unit, storage cabinets for tools,

consumables, and documentation. This container also contains a local magnetic

generator unit that powers the compressors, system controllers, cooling and

ventilation units, fire suppression system, and module lighting.

At the centre of the upper level, above the cylinder group container, is a

container with a Pelton bucket turbine, generators based on permanent magnets

and mounted on both sides of the turbine shaft, with a total output of 5, 8 or

10 MW. The generators are equipped with control units and emergency shutdown

systems. The turbine is enclosed in a casing, to which the nozzle and deflection

inserts are attached via flanged connections. The nozzle has a conical shape

and is positioned to deliver the heavy liquid jet from above, targeting the

centre of the bucket blade edge at an optimal 90° angle. A pneumatically operated

valve is installed in front of the nozzle, connected to a tee that merges two

fluid supply lines from the impulse accumulator. The deflection inserts return

the jet into the buckets, allowing recovery of residual kinetic energy.

On one side of the central container in the upper row, above the control room,

is a container housing inverters, transformers, and connection switchgear.

The inverters stabilise and synchronise frequency and voltage for the

transformers. The transformers produce output voltage of either 6.3 kV or 11 kV

at 50 or 60 Hz. The electrical interface is achieved through three switchgear

units: one common and one for each transformer.

On the opposite side, above the compressor container, is a container with two

supercapacitor banks for energy storage and continuous delivery. This container

also includes a high-speed EV charging module with a plug-in station.